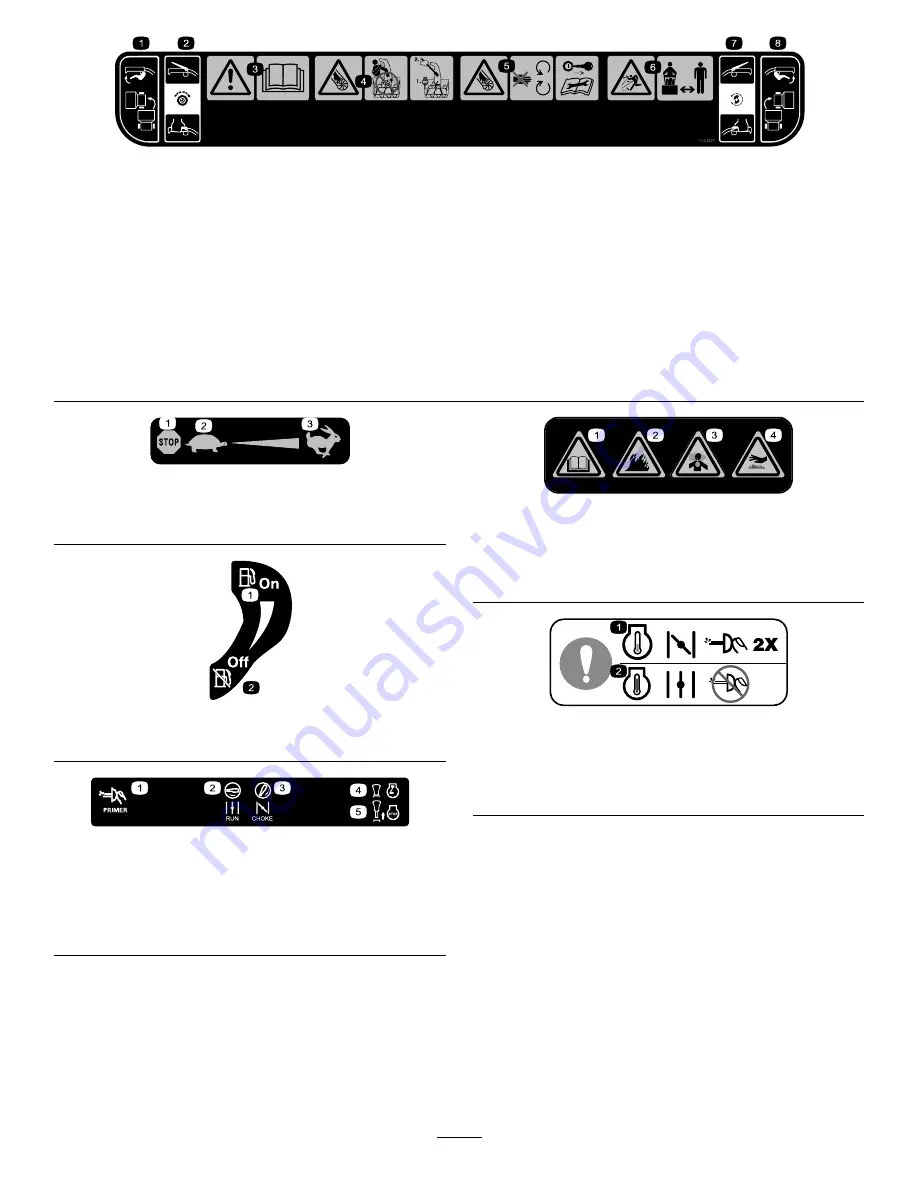

112-6627

1.

Left turn control

3.

Warning—read the

Operator’s Manual.

5.

Cutting/dismemberment

hazard, impeller—keep

away from moving parts;

remove the ignition key and

read the instructions before

servicing or performing

maintenance.

7.

Auger/impeller

drive—squeeze the lever to

engage; release the lever

to disengage.

2.

Traction drive—squeeze

the lever to engage; release

the lever to disengage.

4.

Cutting/dismemberment

hazard, impeller—do

not place your hand

in the chute; stop the

engine before leaving the

operator’s position, use the

tool to clear the chute.

6.

Thrown object

hazard—keep bystanders

a safe distance from the

snowthrower.

8.

Right turn control

Briggs Part No. 273676

1.

Stop

3.

Fast

2.

Slow

Briggs Part No. 274681

1.

Fuel—On

2.

Fuel—Off

Briggs Part No. 276923

1.

Primer

4.

Ignition key in

(Engine—Run)

2.

Choke off (Run)

5.

Ignition key out

(Engine—Stop)

3.

Choke on (Choke)

Briggs Part No. 276925

1.

Warning—read the

Operator’s Manual.

3.

Warning—toxic gas

inhalation hazard.

2.

Warning—fire hazard.

4.

Warning—hot

surface/burn hazard.

Briggs Part No. 277566

1.

When starting a cold

engine, close the choke

and press the primer two

times.

2.

When starting a warm

engine, open the choke

and do not press the

primer.

6

Summary of Contents for 38637C

Page 30: ...Notes 30 ...

Page 31: ...Notes 31 ...