g030446

Figure 25

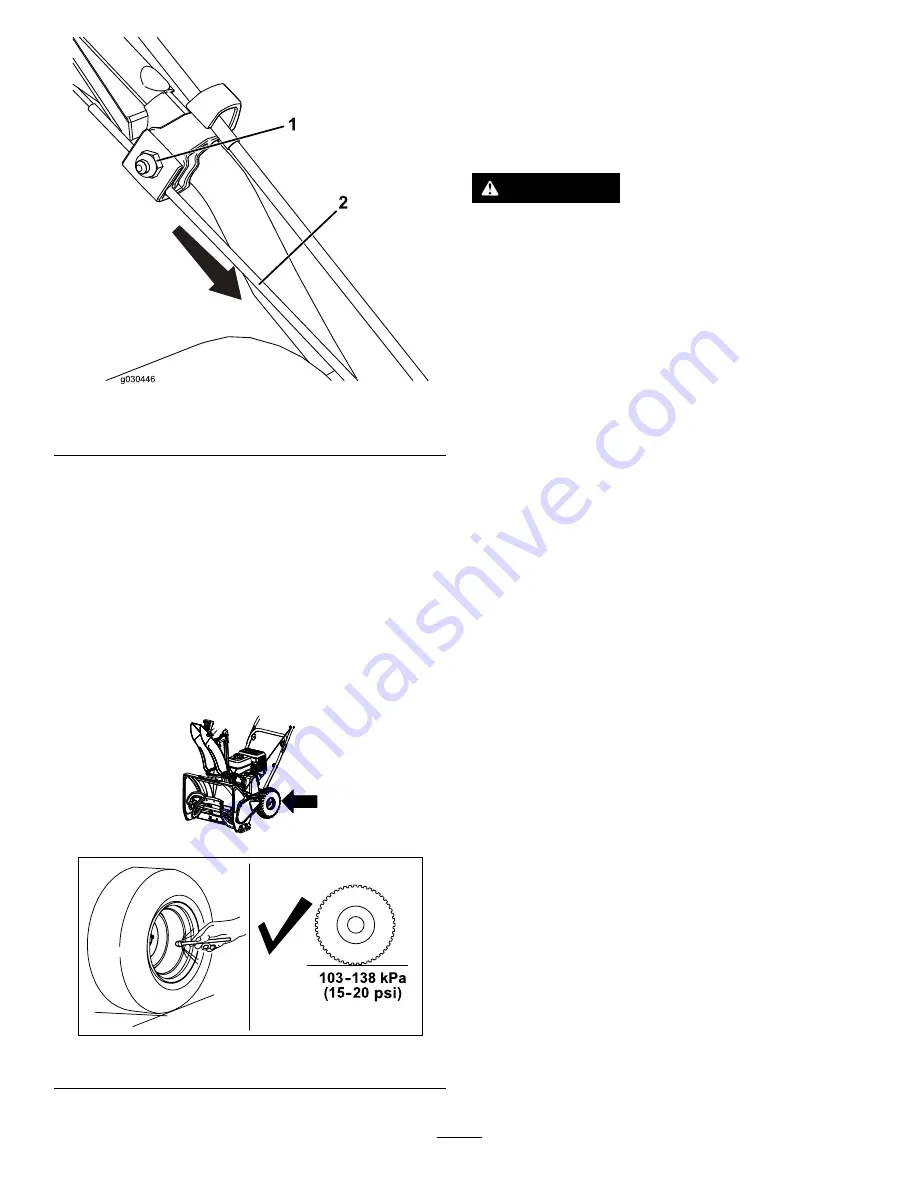

1.

Nut

2.

Cable

2.

Pull the cable down to remove most of the slack

in the cable (

).

Important:

Do not remove all the slack

from the cable. Removing all the slack from

the cable may cause the wheels to engage

without engaging the self-propel handle.

3.

Tighten the nut (

Checking the Tire Pressure

Service Interval:

Yearly

g210347

g211051

Figure 26

Storage

Preparing the Machine for

Storage

WARNING

Fuel fumes are highly flammable, explosive,

and dangerous if inhaled. If you store the

product in an area with an open flame, the fuel

fumes may ignite and cause an explosion.

•

Do not store the machine in a house (living

area), basement, or any other area where

ignition sources may be present, such

as hot water and space heaters, clothes

dryers, furnaces, and other appliances.

•

Do not tip the machine either forward

or backward with fuel in the fuel tank;

otherwise, fuel may leak out of the

machine.

•

Do not store the machine with its handle

tipped down onto the ground; otherwise,

oil leaks into the engine cylinder and onto

the ground, and the engine does not start

or run.

1.

On the last refueling of the season, add fuel

stabilizer to fresh fuel as directed by the engine

manufacturer.

Important:

Do not store fuel longer

than that suggested by the fuel-stabilizer

manufacturer.

2.

Run the engine for 10 minutes to distribute the

conditioned fuel through the fuel system.

3.

Shut off the engine, allow it to cool, and siphon

the fuel tank or run the engine until it shuts off.

4.

Start the engine and run it until it shuts off.

5.

Choke or prime the engine, start it a third time,

and run the engine until it does not start.

6.

Drain the fuel in the carburetor through the

carburetor-drain bolt into an approved gasoline

container.

7.

Dispose of unused fuel properly. Recycle it

according to local codes, or use it in your

automobile.

8.

While the engine is still warm, change the engine

oil. Refer to

Changing the Engine Oil (page 13)

.

9.

Remove the spark plug.

16

Summary of Contents for 38720

Page 18: ...Notes ...

Page 19: ...Notes ...