Form No. 3357-963 Rev B

BBA Compliance Kit

for Multi-Pro 1250 Turf Sprayer

Model No. 41339

Installation Instructions

Note:

Teflon tape is used during the installation of this kit. The tape is used to wrap threads of fittings before

assembly. Threads should be wrapped from left to right, starting at the base and traveling to the tip of fitting (if

looking down the axis of a fitting, tape should be wrapped clockwise from back to front).

Note:

A non-petroleum based lubricant, such as vegetable oil, will be required for the installation of this kit.

Note:

Determine the left and right sides of the machine from the normal operating position.

•

The Compliance Kit comprises three separate

kits: the Spray Gun Kit, the Rinse Kit and the CE

compliance kit. The following setup instructions

install each kit in order to keep parts from separately

packaged kits together during installation for clarity.

It is acknowledged the resulting instructions that

follow have steps that rework installations performed

in preceding steps.

•

Disregard any installation instructions found in

those individual kits.

•

Loose parts not packaged within individual kits are

denoted as BBA kit parts in this kit.

Loose Parts

Use the chart below to verify that all parts have been shipped.

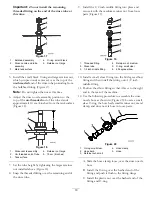

Procedure

Description

Qty.

Use

1

No parts required

–

Preparing the machine.

Hose hook, single bend

1

Spray gun bracket

1

Carriage bolt (5/16 x 3/4 inch)

2

2

Locknut (5/16 inch)

2

Install the hose hooks (Spray Gun Kit).

Control valve

1

Control valve bracket

1

Phillips screw

2

Support bracket (for Multi-Pro Sprayers)

1

Flange-head bolt (1/4 x 3/4 inch)

4

Flange nut (1/4 inch)

4

Tee assembly

1

Pressure gauge

1

Barbed fitting (1/2 inch)

1

3

Retainer fork, large

1

Install the control valve (Spray Gun Kit).

Hose, long

1

O-ring, small clear

1

Spray gun

1

4

Hose clamp, small

1

Install the spray gun (Spray Gun Kit).

Bulkhead

1

5

Plastic ring nut

1

Install the rinse tank bulkhead fitting

(Rinse Kit).

© 2007—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com.

Original Instructions (EN)

Printed in the USA.

All Rights Reserved