Breaking in a New Sprayer

To provide proper performance and long sprayer life, follow

these guidelines for the first 100 operating hours:

•

Check the fluid and engine oil levels regularly and be alert

for indications of overheating in any component of the

sprayer.

•

After filling the tank, check the tank straps for any play.

Tighten as necessary.

•

After starting a cold engine, let it warm up for about

15 seconds before accelerating.

•

Avoid hard braking situations for the first several hours of

new sprayer break-in operation. New brake linings may

not be at optimum performance until several hours of use

has caused the brakes to become burnished (broken-in).

•

Avoid racing the engine.

•

Refer to the Maintenance section for any special low hour

checks.

Operating the Sprayer

To operate the Multi-Pro Sprayer first fill the spray tank, then

apply the solution to the work area, and finally clean the tank.

It is important that you complete all three of these steps in

succession to avoid damaging the sprayer. For example, do

not mix and add chemicals in the spray tank at night and then

spray in the morning. This would lead to separation of the

chemicals and possible damage to the sprayer components.

CAUTION

Chemicals are hazardous and can cause personal

injury.

•

Read the directions on the chemical labels

before handling the chemicals and follow

all manufacturer recommendations and

precautions.

•

Keep chemicals away from your skin. Should

contact occur, wash the affected area thoroughly

with soap and clean water.

•

Wear goggles and any other protective

equipment recommended by the chemical

manufacturer.

The Multi-Pro Sprayer has been specifically designed to have

high durability in order to give it the long sprayer life you

need. Different materials have been chosen for specific

reasons at different locations on your sprayer to meet this

goal. Unfortunately there is no single material which is

perfect for all foreseeable applications.

Some chemicals are more aggressive than others and each

chemical interacts differently with various materials. Some

consistencies (e.g. wettable powders, charcoal) are more

abrasive and lead to higher wear rates. If a chemical is

available in a formulation that would provide increased life to

the sprayer, use this alternative formulation.

As always, remember to clean your sprayer thoroughly after

all applications. This will do the most to ensure your sprayer

has a long and trouble free life.

Note:

If you have questions or need additional information

regarding the spray control system, refer to the Operators

Manual supplied with the system.

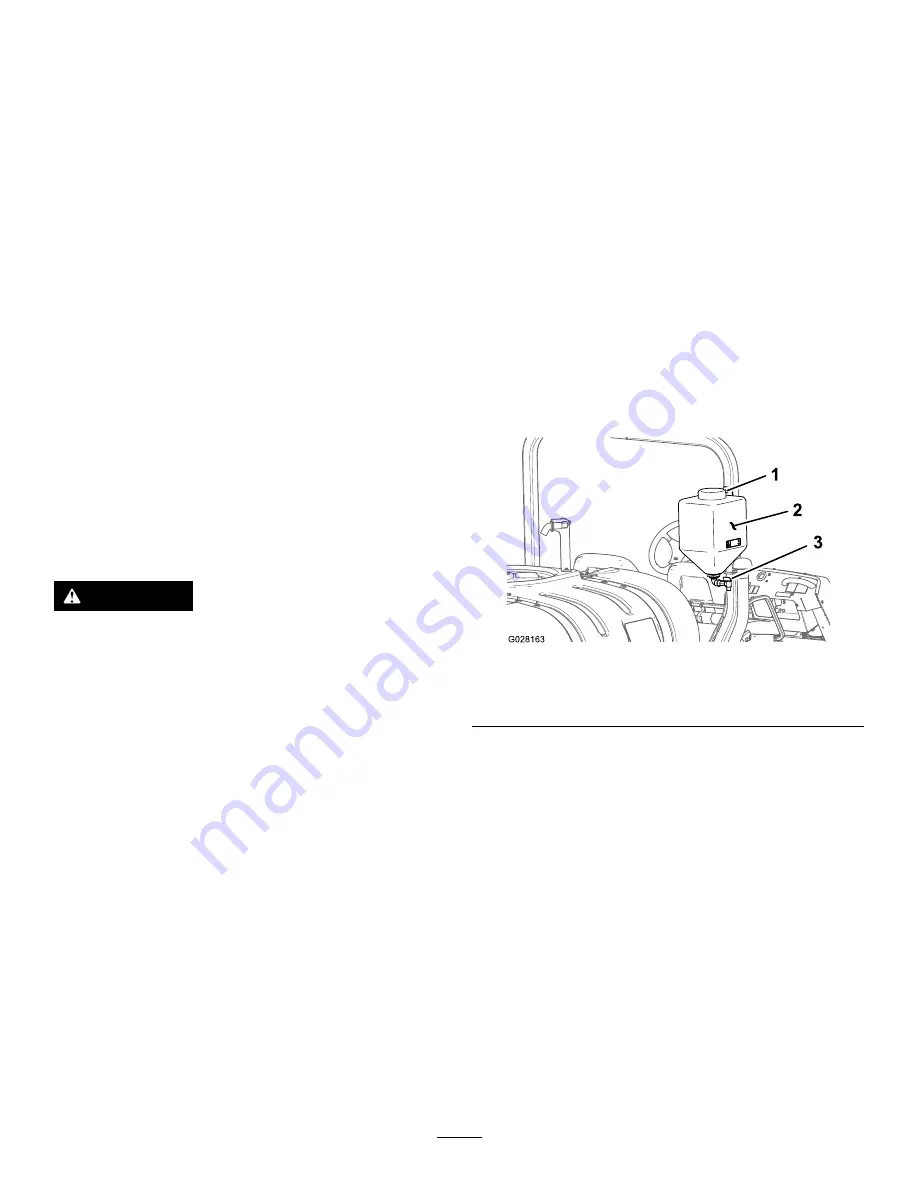

Filling the Fresh Water Tank

Always fill the fresh water tank with clean water before

handling or mixing any chemicals.

The fresh water tank is located on the ROPS, behind the

passenger seat (

). It supplies a source of fresh water

for you to wash chemicals off of your skin, eyes, or other

surfaces in the case of accidental exposure.

To fill the tank, unscrew the cap on the top of the tank and

fill the tank with fresh water. Replace the cap.

To open the fresh water tank spigot, turn the lever on the

spigot.

Figure 34

1.

Filler cap

3.

Spigot

2.

Fresh water tank

Filling the Spray Tank

Important:

Ensure that the chemicals you will be using

are compatible for use with Viton (see the manufacturer's

label; it should indicate if it is not compatible). Using a

chemical that is not compatible with Viton will degrade

the O-rings in the sprayer, causing leaks.

Important:

The tank markings are for reference only

and cannot be considered accurate for calibration.

Important:

After filling the tank for the first time, check

the tank straps for any play. Tighten as necessary.

1.

Stop the sprayer on a level surface, stop the engine,

and set the parking brake.

2.

Determine the amount of water needed to mix the

amount of chemical you need as prescribed by the

chemical manufacturer.

3.

Open the tank cover on the spray tank.

31