cylinders are fully retracted whenever you move

the sprayer from one spraying area to another or

move to a storage or cleaning area.

Turf Care Precautions while

Operating in Stationary Modes

Important:

Under some conditions, heat from the

engine, radiator, and muffler can potentially damage

grass when operating the sprayer in a stationary mode.

Stationary modes include tank agitation, hand spraying

with a spray gun, or using a walking boom.

Use the following precautions:

•

Avoid

stationary spraying when conditions are very hot

and/or dry, as turf can be more stressed during these

periods.

•

Avoid

parking on the turf while stationary spraying. Park

on a cart path whenever possible.

•

Minimize

the amount of time the machine is left

running over any particular area of turf. Both time and

temperature affect how much the grass may be damaged.

•

Set the engine speed as low as possible

to achieve the

desired pressure and flow. This will minimize the heat

generated and the air velocity from the cooling fan.

•

Allow heat to escape

upward from the engine

compartment by raising the seat assemblies during

stationary operation rather than being forced out under

the vehicle.

Spraying Tips

•

Do not overlap areas that you have previously sprayed.

•

Watch for plugged nozzles. Replace all worn or damaged

nozzles.

•

Use the master boom switch to stop the spray flow before

stopping the sprayer. Once stopped, use the neutral

engine speed control to hold the engine speed up to keep

the agitation running.

•

You will obtain better results if the sprayer is moving

when you turn the booms on.

Unclogging a Nozzle

If a nozzle becomes clogged while you are spraying, you can

clean it using a hand spray bottle of water or a toothbrush.

1.

Stop the sprayer on a level surface, stop the engine,

and set the parking brake.

2.

Set the master boom switch to the Off position and

then set the pump switch to the Off position.

3.

Remove the clogged nozzle and clean it using a spray

bottle of water or a toothbrush.

Selecting a Nozzle

Note:

Refer to the nozzle selection guide that is available

through your Authorized Toro Dealer.

The turret bodies can accept up to 3 different nozzles. To

select the desired nozzle:

1.

Stop the sprayer on a level surface, stop the engine,

and set the parking brake.

2.

Set the master boom switch to the Off position and set

the pump switch to the Off position.

3.

Rotate the turret of the nozzles in either direction to

the correct nozzle.

Cleaning the Sprayer

Important:

You must always empty and clean the

sprayer immediately after each use. Failure to do so

may cause the chemicals to dry or thicken in the lines,

clogging the pump and other components.

Toro recommends using the approved rinse kit for this

machine. Contact your Authorized Toro Dealer for more

information.

Clean the spray system after

each

spraying session. To

properly clean the spray system:

•

Use three separate rinses.

•

Use the cleaners and neutralizers as recommended by the

chemical manufacturers.

•

Use pure clean water (no cleaners or neutralizers) for the

last

rinse.

1.

Stop the sprayer, set the parking brake, and turn off

the engine.

2.

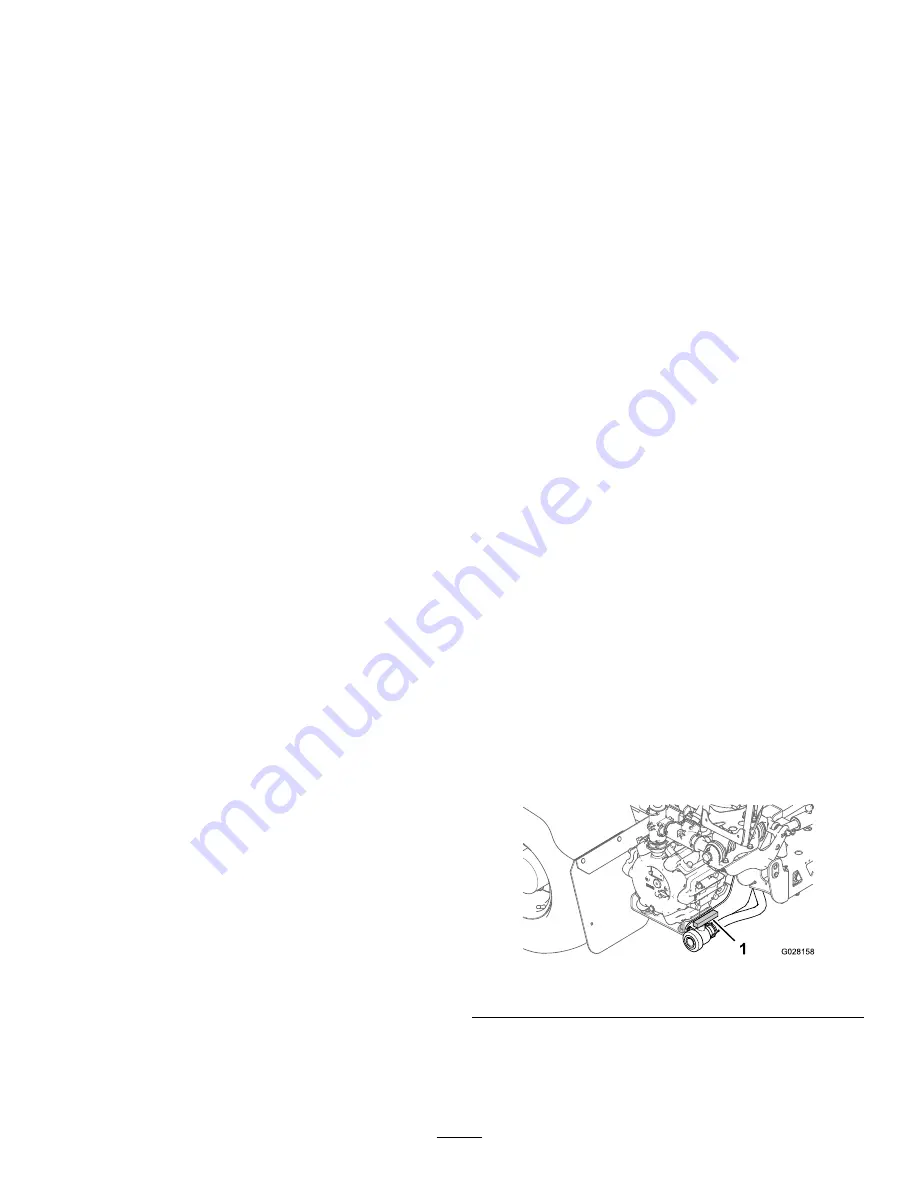

Locate the tank drain valve on the rear of the machine

(

).

Note:

The valve is to the rear of pump, attached to

the support bracket.

Figure 35

1.

Tank drain handle

Open the valve to drain any unused material from the

tank and dispose of it according to local codes and the

material manufacturer's instructions (

). After

draining, remove the lynch pin on the bracket securing

33