Note:

Ensure that the dust valve os aligned between 5

to 7 o’clock position when viewed from the end.

9.

Lower the passenger seat.

Replacing a the Filter Element

Service Interval:

Every 100 hours Replace the air filter

element more often in dusty, dirty

conditions.

1.

If you are installing a new filter, inspect the new air

filter element for shipping damage, including the

sealing end of the filter.

Important:

Do not install a damaged filter.

2.

Wipe clean the dust cap and air cleaner body (

3.

Lift the coolant overflow tank up and off of the

tank-support bracket(

).

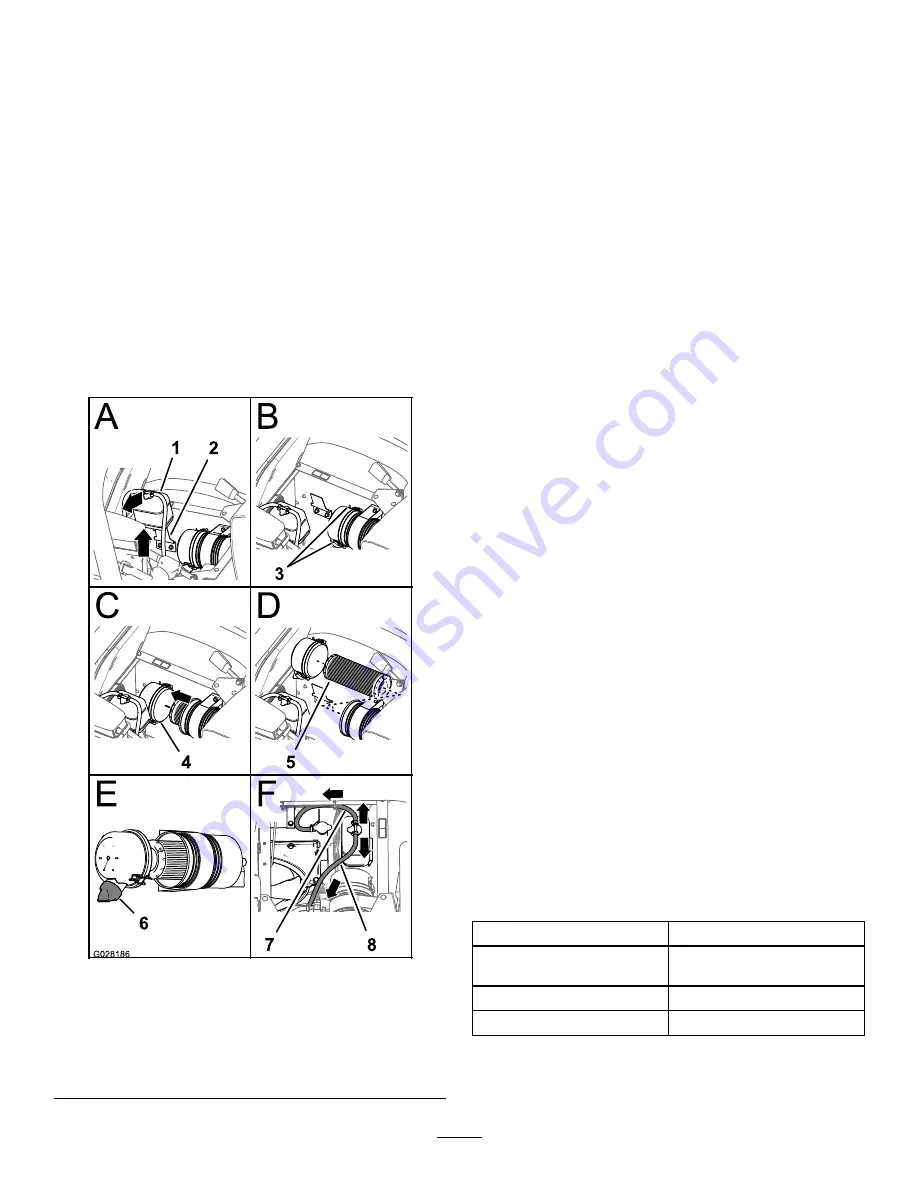

Figure 57

1.

Coolant overflow tank

5.

Air filter element

2.

Tank-support bracket

6.

Dust valve (5 to 7 o’clock

position)

3.

Latch (dust cap)

7.

Pressure relief hose

4.

Dust cap

8.

Tank-vent hose

4.

Loosen the 2 latches that secure the dust cap to the air

cleaner body (

5.

Gently slide the old filter element out of the air cleaner

body to reduce the amount of dust dislodged.

Note:

Avoid knocking the filter element against the

air cleaner body.

6.

Wipe clean the inside of the dust cap, air cleaner body,

and dust valve with a damp rag (

and

7.

Insert the air filter element into the air cleaner body

(

).

Note:

Ensure that the filter is seated in the air cleaner

body properly by applying pressure to the outer rim of

the filter element when you install it. Do not press on

the flexible center part of the filter.

8.

Install the cover onto air cleaner body and secure the

cover with the 2 latches (

Note:

Ensure that the dust valve os aligned between

5 to 7 o’clock position when viewed from the end

(

).

9.

Align the coolant overflow tank to the tank-support

bracket and seat the tank firmly (

).

Important:

Ensure that the pressure relief hose

is routed forward and down and tank-vent hose is

routed rearward as shown in

10.

Lower the passenger seat.

Servicing the Engine Oil

Service Interval:

After the first 50 hours—Change the

engine oil and oil filter

Every 200 hours—Change the engine oil (including

synthetic oil) and oil filter Change the oil and filter

more often when operating the machine under heavy

load or in high temperature.

Every 400 hours/Yearly (whichever comes

first)—Complete all yearly maintenance procedure

specified in the

engine operator's manual.

Crankcase oil capacity:

5.1 L (5.4 US qt) with the filter.

•

Oil type:

API service classification SL or higher.

•

Oil viscosity:

refer to the engine oil viscosity table below.

Engine Oil Viscosity Table

Ambient temperature range

Oil viscosity

Above 25 C (77 F)

SAE30, SAE10W-30, or

SAE15W-40

0 C to 25 C (32 F to 77 F)

SAE20 or SAE10W-30

0 C to 20 C (32 F to -4 F)

SAE10W or SAE10W-30

Toro Premium Engine Oil is available from your distributor

in either 15W40 or 10W30 viscosity. Refer to the

Parts Catalog

for part numbers.

44