17

Maintenance

3.

Remove the spark plug.

4.

Hand thread the new spark plug, turning it clockwise.

5.

Tighten with a socket. (Torque to 170 in.lb. minimum,

190 in.lb. maximum.

Do not overtighten).

CAUTION:

Be careful not to cross-thread the spark plug. Cross-

threading will seriously damage the product.

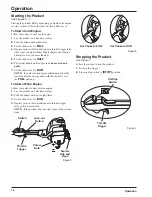

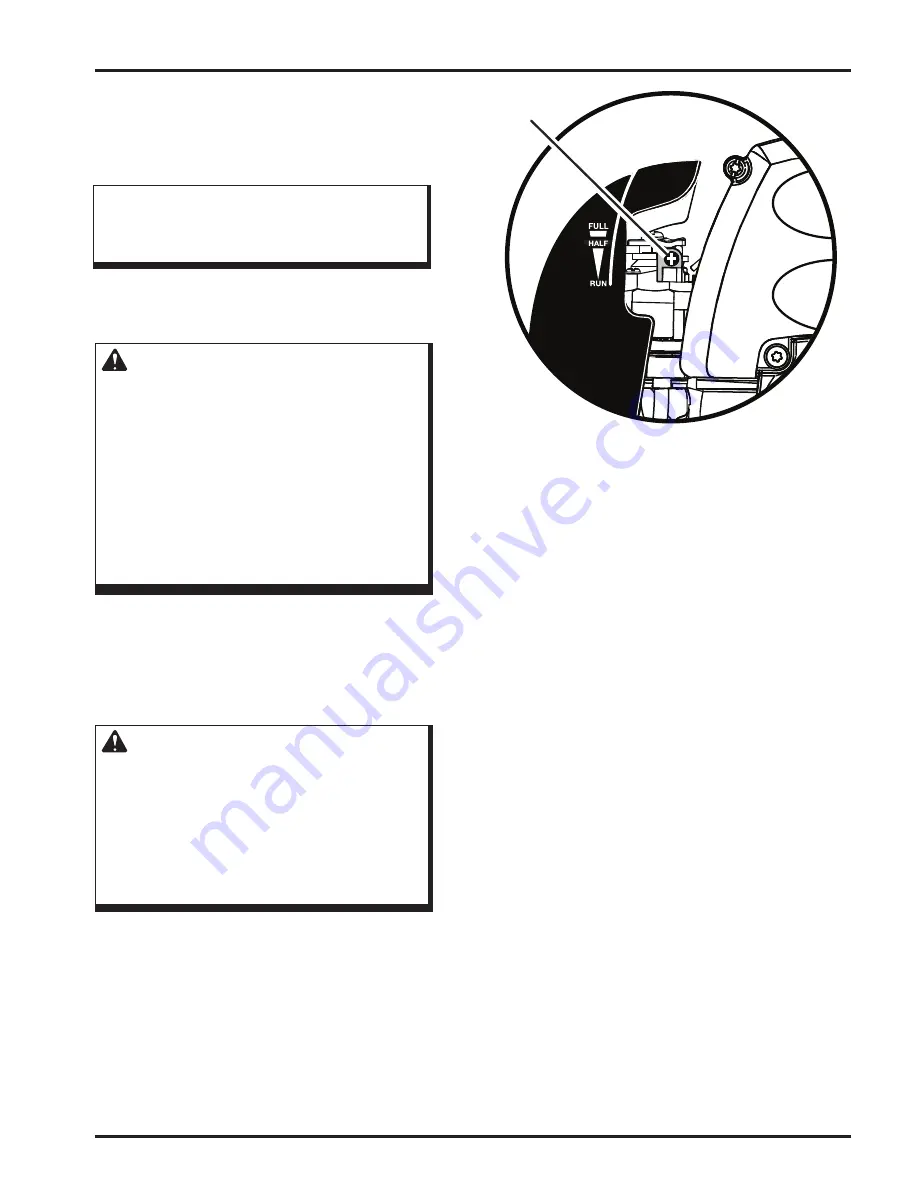

Idle Speed Adjustment

See Figure 11.

WARNING:

The blade/cutting head will move when

adjusting the idle speed. Wear all protective

clothing and keep all bystanders, children, and

pets at least 50 ft. away. Make adjustments with

the unit supported by hand so that the blade/

cutting head does not contact the ground or any

object. Keep all parts of your body away from

the blade/cutting head and muffler. Failure to

follow these instructions could result in serious

personal injury.

If the cutting attachment turns at idle, the idle speed screw

needs adjusting on the engine. Turn the idle speed screw

counterclockwise to reduce the idle RPM and stop the cut-

ting attachment movement. If the cutting attachment still

moves at idle speed, contact a service dealer for adjustment

and discontinue use until the repair is made.

WARNING:

The cutting attachment should never turn at idle.

Turn the idle speed screw counterclockwise

to reduce the idle RPM and stop the cutting

attachment, or contact a service dealer for

adjustment and discontinue use until the repair

is made. Serious personal injury may result

from the cutting attachment turning at idle.

Idle Speed

Screw

Maintenance

Figure 11

Storing the Product

Storing the product differs depending on the amount of time

it will be in storage.

Note:

If the product includes an attachment, place the stor-

age cap on the end of the attachment shaft and hang it up to

store.

To Store the Product Short Term:

1.

Clean all foreign material from the product.

2.

Store the product in a well-ventilated place that is inac-

cessible to children.

To Store the Product Long Term:

If you do not intend to use the product for more than one

month, follow the storage procedures below.

Follow these steps to store the product long term.

1.

Drain all of the fuel from the tank into a container ap-

proved for gasoline.

2.

Run the engine until it stops.

3.

Clean all foreign material from the product.

4.

Store the product in a well-ventilated place that is inac-

cessible to children.

Note:

Keep the product away from corrosive agents

such as garden chemicals and de-icing salts.

Note:

Abide by all federal and local regulations for the

safe storage and handling of gasoline.

Transporting the Product

1.

Drain the fuel mixture into a container that is approved

for use with gasoline.

2.

Carry the product by the front handle.

3.

Secure the product in your vehicle or on a trailer.

Summary of Contents for 51945

Page 22: ...Notes...