GB–13

3.

Check the distance between the top of the

handgrip and the bottom of the auger/impeller

control lever (Fig. 6 & 9). Distance should be

approximately four inches. This is a

preliminary setting only.

4.

Compress auger/impeller control lever slowly

toward handgrip. The amount of force to

compress the lever will increase noticeably when

slack is removed from the drive belt

(approximately one–half of lever movement).

Adjustment is correct when the force begins to

increase and the distance between the top of the

handgrip and the bottom of the auger/impeller

control lever is one to two inches.

Note:

If force does not noticeably increase,

remove the belt cover (refer to

Replacing Auger/ Impeller Drive Belt,

steps 1–2, page 15) and measure the

one to two inch dimension above the

handgrip at the point where the slack is

removed from the auger/impeller drive

belt.

5.

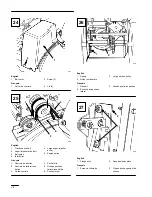

To adjust the distance, remove clevis pin, loosen

jam nut and thread clevis up or down to increase

or decrease distance between handgrip and

auger/impeller control lever (Fig. 8).

6.

When adjustment is correct, install clevis pin

and secure it in place with the cotter pin. Tighten

jam nut to secure clevis (Fig. 8).

Install Chute Control Rod

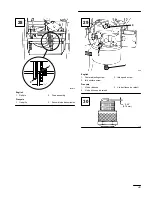

1.

Assemble chute control bracket and rod to left

side of handle with capscrew and locknut. Leave

locknut loose until assembly is completely

mounted (Fig. 10).

2.

Apply No. 2 general purpose grease to worm

gear. Next, mount worm gear and bracket to

mounting flange and secure with pyramidal

washer and locknut (Fig. 11).

3.

Slide worm gear into teeth of chute retaining

ring and tighten locknut (Fig. 11).

4.

Tighten the locknut securing chute control

bracket against left handle (Fig. 10).

5.

Check operation of chute control rod. Move

worm gear slightly outward if binding is evident.

Secure Chute Deflector

1.

Pivot deflector upward and back until deflector

stop passes over lip on top of chute.

2.

Secure left side of deflector to discharge chute

using parts as illustrated in Figure 12. Make sure

rubber washer and friction plate are positioned

between chute and deflector and friction plate

tabs fit into holes in deflector. See Figure 12 for

proper installation sequence of parts.

Note:

Concave side of curved washer goes

against large flat washer.

3.

Tighten nuts on both sides of deflector. Do not

over–tighten nuts so that excessive force is

required to change deflector angle.

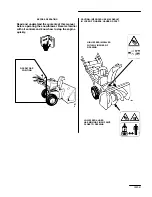

Check Tire Pressure

IMPORTANT: Check pressure of tires

because they are over–inflated at the factory

for shipping. Before the snowthrower is

operated, reduce pressure in both tires to

7–15 psi equally.