Contents

Introduction .................................................................. 2

Safety ........................................................................... 3

Safe Operating Practices........................................... 3

Safety and Instructional Decals ................................. 5

Setup ............................................................................ 7

Product Overview .......................................................... 7

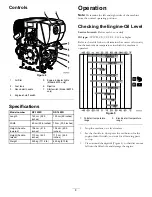

Operation ..................................................................... 8

Checking the Engine-Oil Level.................................. 8

Checking the Water Trap .......................................... 9

Cleaning Debris from the Machine............................. 9

Adding Fuel...........................................................10

Starting and Stopping the Engine..............................11

Operating the Compactor........................................12

Transporting the Machine........................................12

Maintenance .................................................................13

Recommended Maintenance Schedule(s) ......................13

Servicing the Air Cleaner .........................................13

Replacing the Fuel Filter ..........................................14

Servicing the Engine Oil..........................................15

Servicing the Eccentric Oil ......................................16

Servicing the Battery ( Model 68075 only)...................17

Servicing the Belt ...................................................18

Storage ........................................................................19

Troubleshooting ...........................................................20

Safety

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with these safety instructions and

always pay attention to the safety alert symbol, which

means

Caution

,

Warning

, or

Danger

—personal safety

instruction. Failure to comply with the instruction may

result in personal injury or death.

Safe Operating Practices

This product is capable of crushing or amputating hands and

feet. Always follow all safety instructions to avoid serious

injury or death.

WARNING

Engine exhaust contains carbon monoxide, and

odorless, deadly poison that can kill you

Do not run the engine indoors or in an enclosed

area.

Training

•

Read the

Operator's Manual

and other training material. If

the operator(s) or mechanic(s) cannot read English, it is

the owner's responsibility to explain this material to them.

•

Become familiar with the safe operation of the equipment,

operator controls, and safety signs.

•

All operators and mechanics should be trained. The

owner is responsible for training the users.

•

Never let children or untrained people operate or service

the equipment. Local regulations may restrict the age of

the operator.

•

The owner/user can prevent and is responsible for

accidents or injuries occurring to himself or herself, other

people or property.

Preparation

•

Evaluate the terrain to determine the proper and safe

actions to perform the job. Only use accessories and

attachments approved by the manufacturer.

•

Wear appropriate clothing including hard hat, safety

glasses, long pants, safety shoes, and hearing protection.

Long hair, loose clothing or jewelry may get tangled in

moving parts.

•

Inspect the area where the equipment is to be used and

remove all objects such as tools, building materials, and

personal items which can be damaged by the machine.

•

Use extra care when handling fuels. They are flammable

and vapors are explosive.

–

Use only an approved container

–

Never remove the fuel cap or add fuel with the engine

running. Allow the engine to cool before refueling.

Do not smoke.

3