Lubrication

Greasing the Machine

Service Interval:

Every 50 hours

When operating the machine under normal conditions,

lubricate all grease fittings for the bearings and

bushings with No. 2 lithium grease. Lubricate the

bearings and bushings immediately after every

washing, regardless of the interval listed. Apply a light

coating of oil onto the control cables.

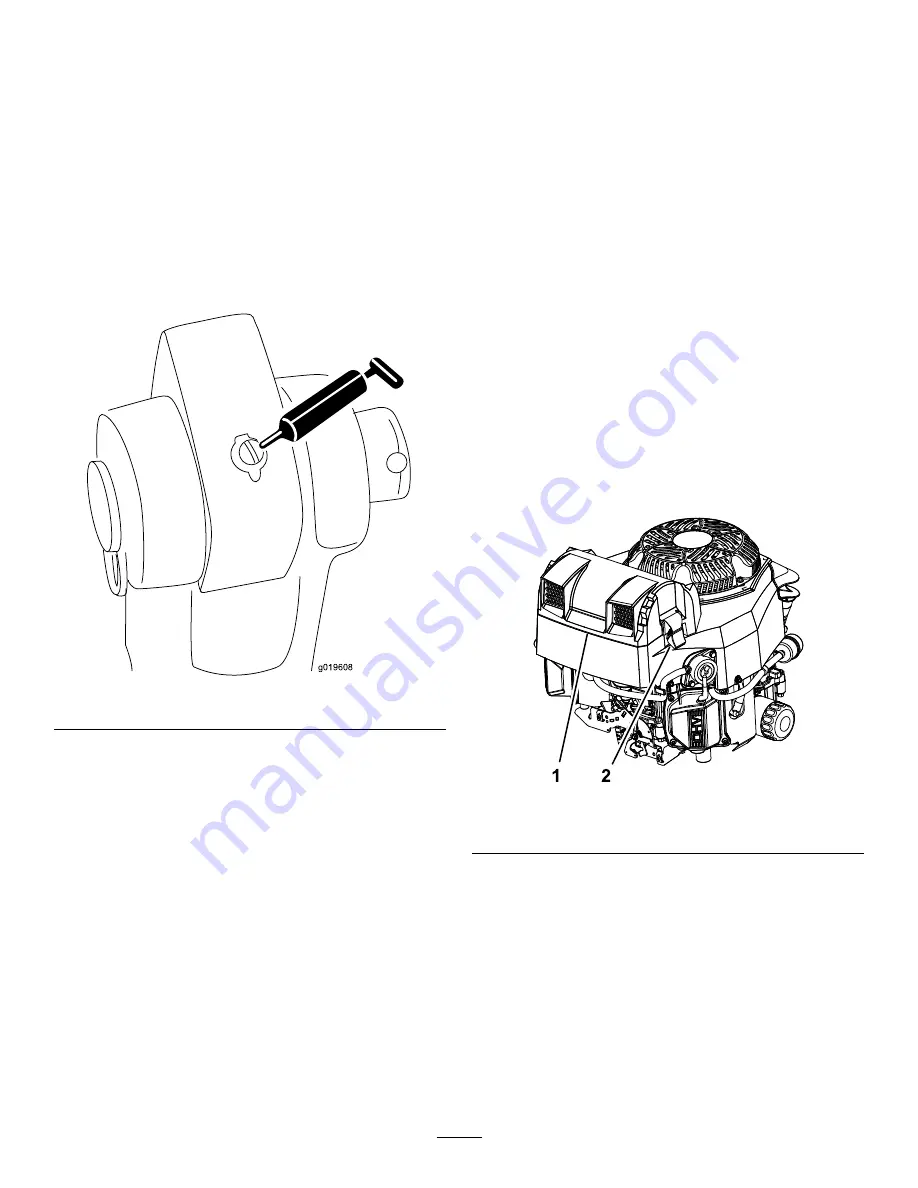

Cylinder pivots (2)—

g019608

Figure 17

Engine Maintenance

Servicing the Air Cleaner

Service Interval:

Every 25 hours—Service or replace

the air-cleaner foam element (more

often under extremely dusty, dirty

conditions).

Every 100 hours—Replace the air-cleaner

paper element (more often under extremely

dusty, dirty conditions).

Note:

Operating the engine with loose or damaged

air-cleaner components could allow unfiltered air into

the engine, causing premature wear and failure.

Note:

Service the air cleaner more often under

extremely dusty, dirty conditions.

Removing the Elements

1.

Rotate the latches outward.

2.

Remove the cover to access the air-cleaner

elements (

g243624

Figure 18

1.

Air-cleaner cover

2.

Air-cleaner latch

3.

Remove the foam and paper elements (

4.

Remove the foam element from the paper

element (

19

Go

to

Discount-Equipment.com

to

order

your

parts