Maintenance

38

m–1889

1

4

3

2

Figure 48

1.

Hair pin cotter and washer

2.

Leveling bracket

3.

Front hole

4.

Rear hole

6.

Now check the front-to-rear blade slope; refer to

Front-to-Rear Blade Slope, page 38.

Front-to-Rear Blade Slope

Check the front-to-rear blade slope any time you

install the mower. Before you check the slope, set the

air pressure in the front and rear tires to the

recommended inflation. Refer to “Tire Pressure”

(page 19) in the Maintenance Section. If the front of

the mower is not within a range of 1/8”–3/8”

(3.5mm–10.5mm) lower than the rear of the mower,

adjust the blade slope using the following

instructions:

1.

Park the machine on a level surface, disengage

the blade control (PTO), shift into neutral, set

the parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2.

Check and adjust side-to-side blade level if you

have not checked the setting; refer to

Side-to-Side Mower Leveling, page 37.

3.

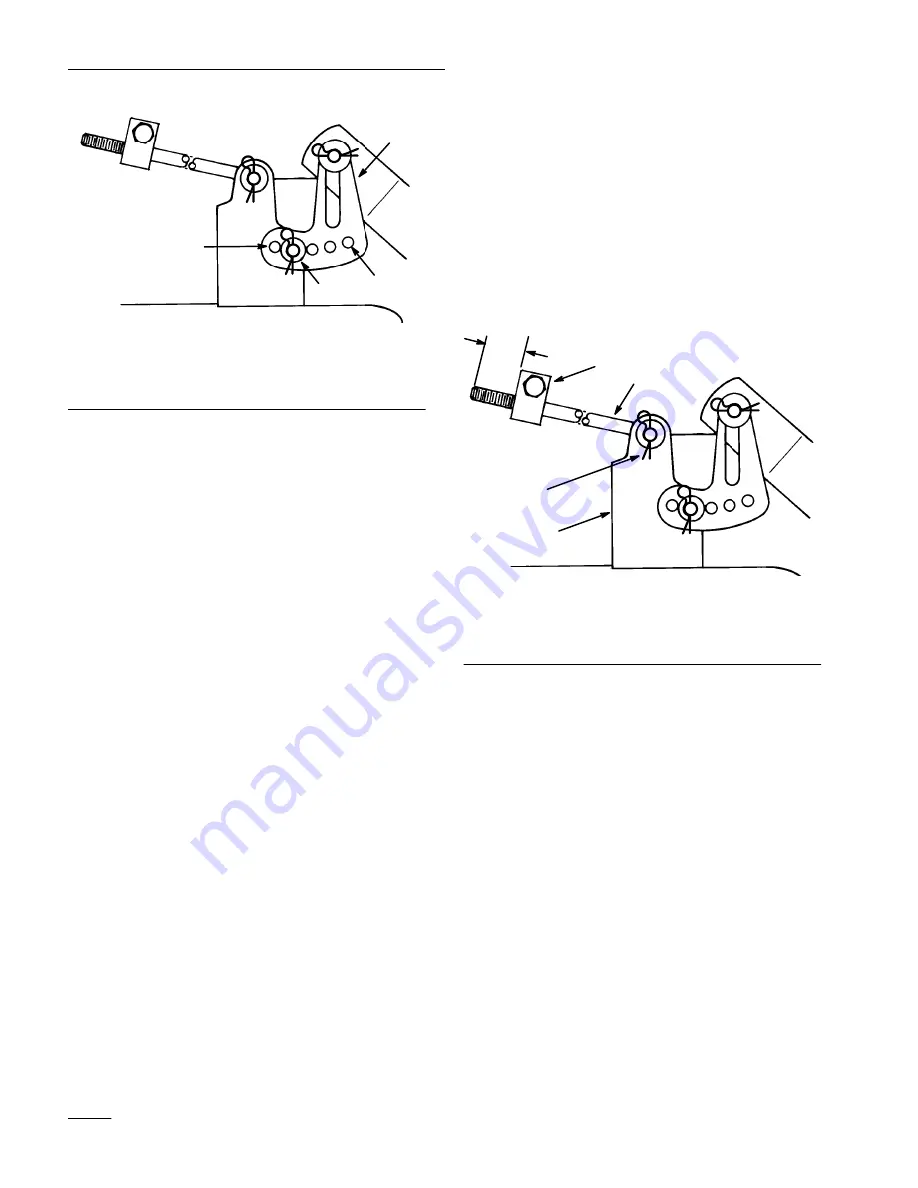

Measure the length of the rod extending out the

front of the adjusting block on the sides of the

chassis (Fig. 49). If the rod length is not 5/8”

(16 mm), remove the hair pin cotter and washer

from the end of the rod (Fig. 49), and turn the

rod until the 5/8” (16 mm) dimension is

obtained. Then install the end of the rod into the

hole in the mower mount and secure in place

with washer and hair pin cotter. Repeat

procedure on the opposite side.

5/8”

(16 mm)

1

2

3

4

1805

Figure 49

1.

Hair pin cotter and washer

2.

Leveling bracket

3.

Front hole

4.

Rear hole

4.

Check the front to rear slope by measuring

between the bottom of the mower

(front center and rear center) and the flat surface

(Fig. 50). If the front is not within a range of

1/8”–3/8” (3.5mm–10.5mm) lower than the rear,

an adjustment is required.

Summary of Contents for 71198

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 4...

Page 8: ...6...

Page 46: ......

Page 47: ......