Maintenance

23

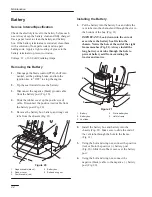

Checking Electrolyte Level

1.

Tip the seat forward to see the battery.

2.

Look at the side of the battery. The electrolyte

must be up to the “UPPER” line (Fig. 22). Do

not allow the electrolyte to get below the

“LOWER” line (Fig. 22).

3.

If the electrolyte is low, add the required amount

of distilled water; refer to Adding Water to the

Battery, page 23.

Figure 22

1.

Filler caps

2.

UPPER line

3.

LOWER line

1

2

3

Adding Water to the Battery

The best time to add distilled water to the battery is

just before you operate the machine. This lets the

water mix thoroughly with the electrolyte solution.

1.

Clean the top of the battery with a paper towel.

2.

Unscrew the filler caps (Fig. 22).

3.

Slowly pour distilled water into each battery cell

until the level is up to the “UPPER” line

(Fig. 22) on the battery case.

IMPORTANT: Do not overfill the battery

because electrolyte (sulfuric acid) can cause

severe corrosion and damage to the chassis.

4.

Screw the filler caps onto the battery.

Charging the Battery

IMPORTANT: Always keep the battery fully

charged (1.260 specific gravity). This is

especially important to prevent battery

damage when the temperature is below 32

°

F

(0

°

C).

1.

Remove the battery from the chassis; refer to

Removing the Battery, page 22.

2.

Check the electrolyte level; refer to Checking

Electrolyte Level, page 23, steps 2–3.

3.

Remove the filler caps from the battery and

connect a 3 to 4 amp battery charger to the

battery posts. Charge the battery at a rate of 4

amperes or less for 4 hours (12 volts). Do not

overcharge the battery. Install the filler caps after

the battery is fully charged.

POTENTIAL HAZARD

•

Charging the battery produces gasses.

WHAT CAN HAPPEN

•

Battery gasses can explode.

HOW TO AVOID THE HAZARD

•

Keep cigarettes, sparks and flames away

from battery.

4.

Install the battery in the chassis; refer to

Installing the Battery, page 22.