4.

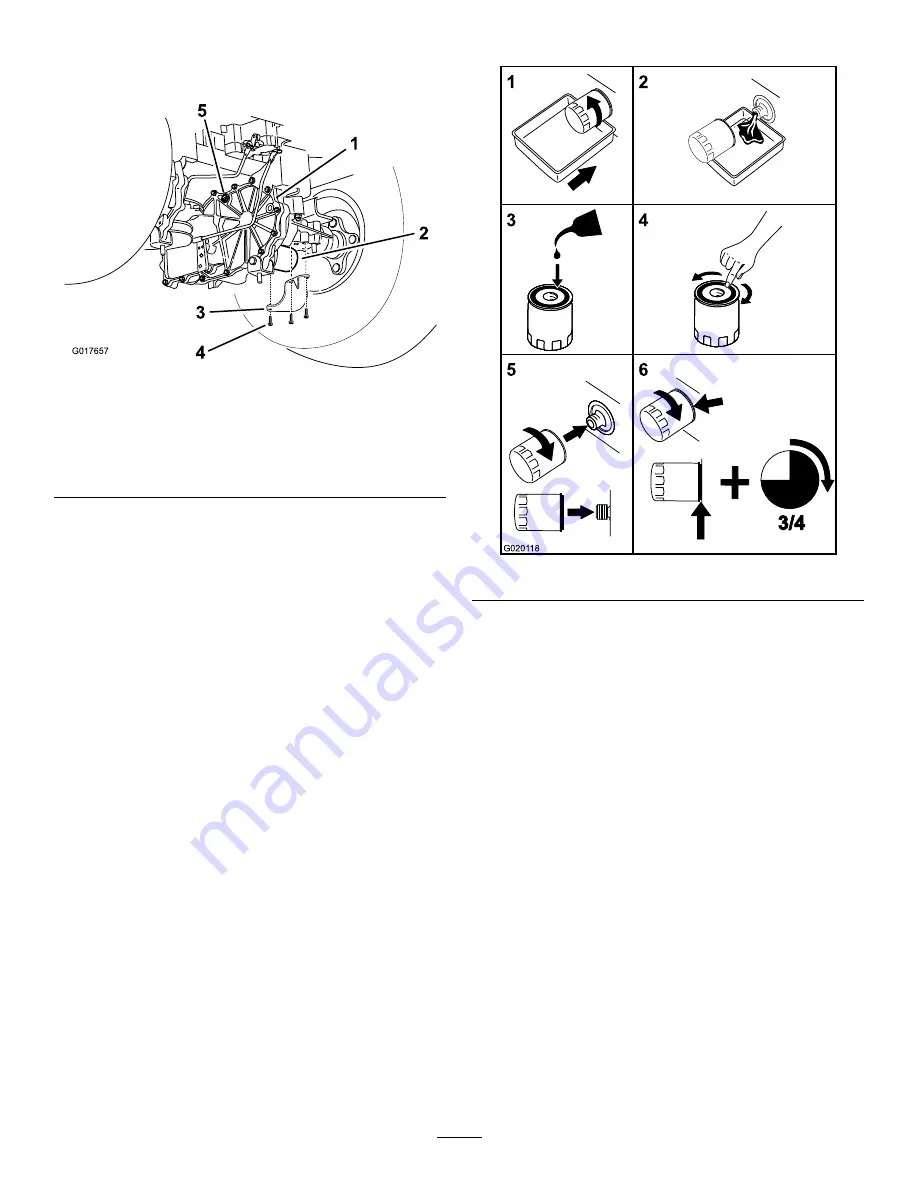

Locate the filter and filter guards on each transaxle

drive system (Figure 50). Remove three screws securing

the filter guard and guard.

G017657

5

1

2

3

4

Figure 50

Right side shown

1.

Transaxle drive

4.

Screws

2.

Oil filter

5.

Vent plug

3.

Filter guard

5.

Carefully clean area around filters. It is important that

no dirt or contamination enter hydraulic system.

6.

Place a container below the filter to catch the oil that

drains when the filter and vent plugs are removed.

7.

Locate and remove the vent plug on each transmission

8.

Unscrew the filter to remove and allow oil to drain

from drive system.

Repeat this procedure for both filters.

Installing the Hydraulic System Filters

1

2

3

4

5

6

3/4

G0201 18

Figure 51

1.

Apply a thin coat of the specified oil on the surface of

the rubber seal of each filter.

2.

Turn the filter clockwise until rubber seal contacts the

filter adapter then tighten the filter an additional 3/4 to

1 full turn. Repeat for the other filter

3.

Install the filter guards over each filter as previously

removed. Use the three screws to secure the filter

guards.

4.

Install the transaxle support. Refer to Figure 49 for the

correct torque values for the nuts and bolts.

Note:

Ensure the transaxle support is installed (Figure

5.

Verify the vent plugs are removed before adding the oil.

6.

Slowly pour the specified oil through expansion

reservoir until oil comes out of

one

of the vent plug

holes. Stop and install that vent plug. Torque the plug

to 180 in-lb (20.3 N-m).

7.

Continue to add oil through the expansion reservoir

until oil comes out of the remaining vent plug hole on

the second transmission. Stop and install that vent

plug. Torque the plug to 180 in-lb (20.3 N-m).

8.

Continue to add oil through the expansion reservoir

until it reaches the FULL COLD line on the expansion

reservoir.

37

Summary of Contents for 74395

Page 10: ...119 8874 1 Low speed 2 High speed 10 ...

Page 50: ...Schematics g017655 Electrical Diagram Rev A 50 ...

Page 51: ...Notes 51 ...