9.

Proceed to the Bleeding the Hydraulic System section.

Important:

Failure to perform the

Bleeding

the Hydraulic System

procedure after changing

hydraulic filters and oil can result in irreparable

damage to the transaxle drive system.

Bleeding the Hydraulic System

1.

Enter the operator's position. Start engine and

move throttle control ahead to 1/2 throttle position.

Disengage parking brake.

A.

Move the bypass levers into the pushing the

machine position; refer to the Pushing the

Machine by Hand section in Operation. With the

bypass valves open and the engine running, slowly

move the motion control levers in both forward

and reverse (5 or 6 times).

B.

Move the bypass levers into the operating

the machine position. With the bypass valve

closed and the engine running, slowly move the

directional control in both forward and reverse

directions (5 to 6 times).

C.

Stop the engine and check the oil level in the

expansion reservoir. Add the specified oil as until

it reaches the FULL COLD line on the expansion

reservoir.

2.

Repeat step 1 until all the air is completely purged from

the system.

When the transaxle operates at normal noise levels and

moves smoothly forward and reverse at normal speeds,

then the transaxle is considered purged.

3.

Check the oil level in the expansion reservoir one last

time. Add the specified oil as until it reaches the FULL

COLD line on the expansion reservoir if necessary.

Mower Maintenance

Servicing the Cutting Blades

Maintain sharp blades throughout the cutting season because

sharp blades cut cleanly without tearing or shredding the grass

blades. Tearing and shredding turns grass brown at the edges,

which slows growth and increases the chance of disease.

Check the cutter blades daily for sharpness, and for any

wear or damage. File down any nicks and sharpen the

blades as necessary. If a blade is damaged or worn, replace

it immediately with a genuine Toro replacement blade. For

convenient sharpening and replacement, you may want to

keep extra blades on hand.

WARNING

A worn or damaged blade can break, and a piece

of the blade could be thrown into the operator's

or bystander's area, resulting in serious personal

injury or death.

•

Inspect the blade periodically for wear or

damage.

•

Replace a worn or damaged blade.

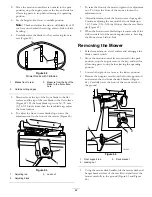

Before Inspecting or Servicing the

Blades

Park the machine on a level surface, disengage the blade

control switch, and move the motion control levers outward

to the park position. Stop the engine and remove the key.

Inspecting the Blades

Service Interval:

Before each use or daily—Check the

cutting blades.

1.

Inspect the cutting edges (Figure 52). If the edges

are not sharp or have nicks, remove and sharpen the

blades; refer to Sharpening the Blades.

2.

Inspect the blades, especially the curved area (Figure

52). If you notice any damage, wear, or a slot forming

in this area (item 3 in Figure 52), immediately install

a new blade.

38

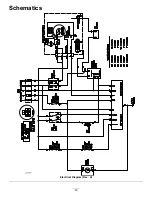

Summary of Contents for 74395

Page 10: ...119 8874 1 Low speed 2 High speed 10 ...

Page 50: ...Schematics g017655 Electrical Diagram Rev A 50 ...

Page 51: ...Notes 51 ...