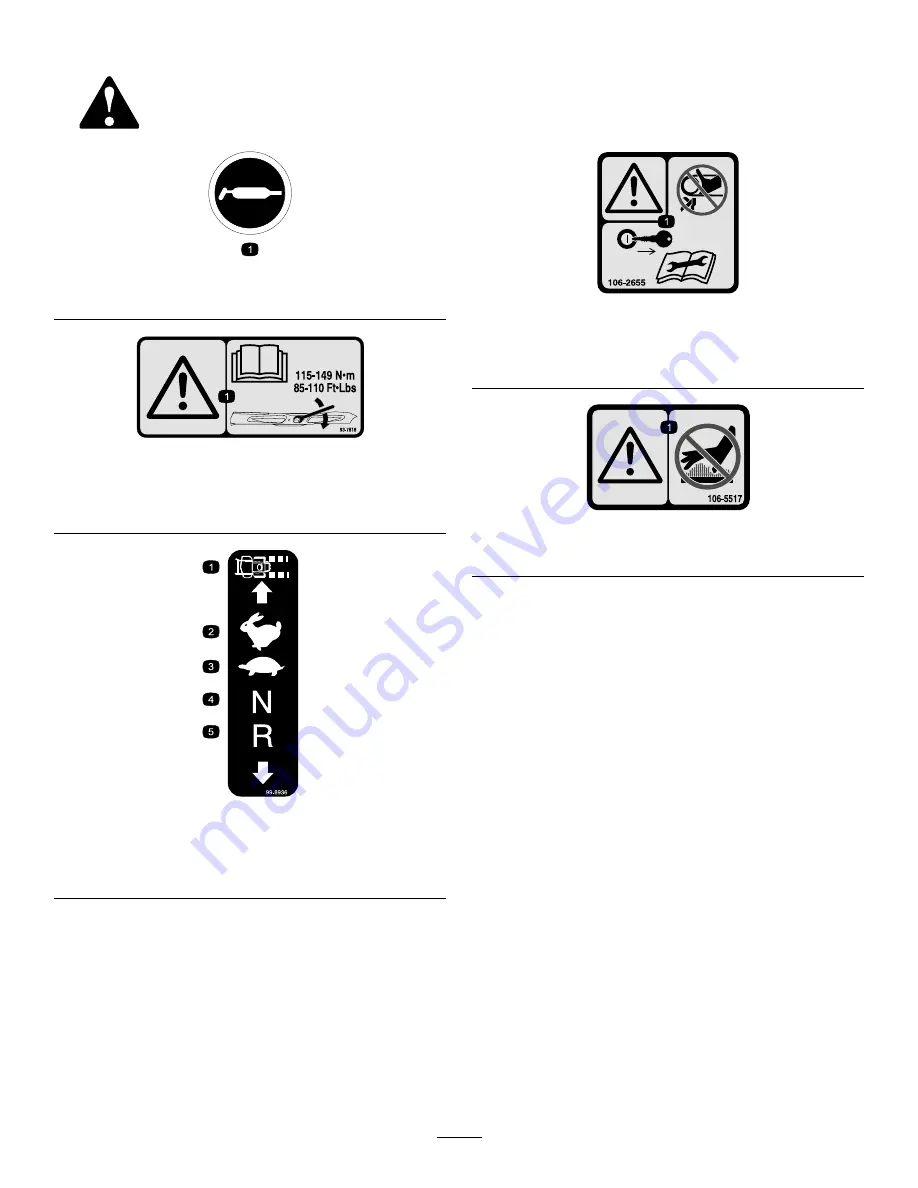

Safety and Instructional Decals

Safety decals and instructions are easily visible to the operator and are located near any area of potential

danger. Replace any decal that is damaged or lost.

58-6520

1.

Grease

93-7818

1.

Warning—read the

Operator's Manual

for instructions on

torquing the blade bolt/nut to 115 to 149 N∙m (85 to 110

ft-lb).

99-8936

1.

Machine speed

4.

Neutral

2.

Fast

5.

Reverse

3.

Slow

106-2655

1.

Warning-do not touch or approach moving belts; remove

the ignition key and read the instructions before servicing

or performing maintenance.

106-5517

1.

Warning—do not touch the hot surface.

8