Breaking in a New Machine

New engines take time to develop full power. Mower

decks and drive systems have higher friction when

new, placing additional load on the engine. Allow

40 to 50 hours of break-in time for new machines to

develop full power and best performance.

Using the Rollover

Protection System (ROPS)

WARNING

To avoid injury or death from rollover: keep

the roll bar in the raised locked position and

use the seat belt.

Ensure that the rear part of the seat is secured

with the seat latch.

WARNING

There is no rollover protection when the roll

bar is in the down position.

•

Lower the roll bar only when absolutely

necessary.

•

Do not wear the seat belt when the roll bar

is in the down position.

•

Drive slowly and carefully.

•

Raise the roll bar as soon as clearance

permits.

•

Check carefully for overhead clearances

(i.e., branches, doorways, electrical wires)

before driving under any objects and do

not contact them.

Important:

Lower the roll bar only when

absolutely necessary.

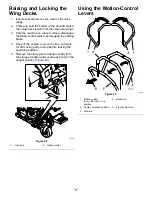

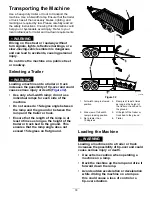

1.

Ensure that the knob is completely latched with

the tabs interlocking as shown in

to lock

the roll bar in the raised position.

2.

To lower the roll bar, apply forward pressure to

the upper part of the roll bar.

3.

Pull both knobs out and rotate them 90° so they

are not engaged (

).

4.

To raise the roll bar, raise the roll bar to the

operate position, rotate the knobs so that they

move partially into the grooves (

5.

Raise the roll bar to the full upright position while

pushing on the upper roll bar and the pins snap

into position when the holes align with the pins

(

).

Important:

Always use the seat belt with the

roll bar in the raised position.

g225804

Figure 8

1.

Upper part of the roll bar

4.

Rotate the knob out 90°

to hold it in the unlatched

position.

2.

Knob in the latched

position

5.

Knob in the unlatched

position

3.

Pull the knob to unlatch.

6.

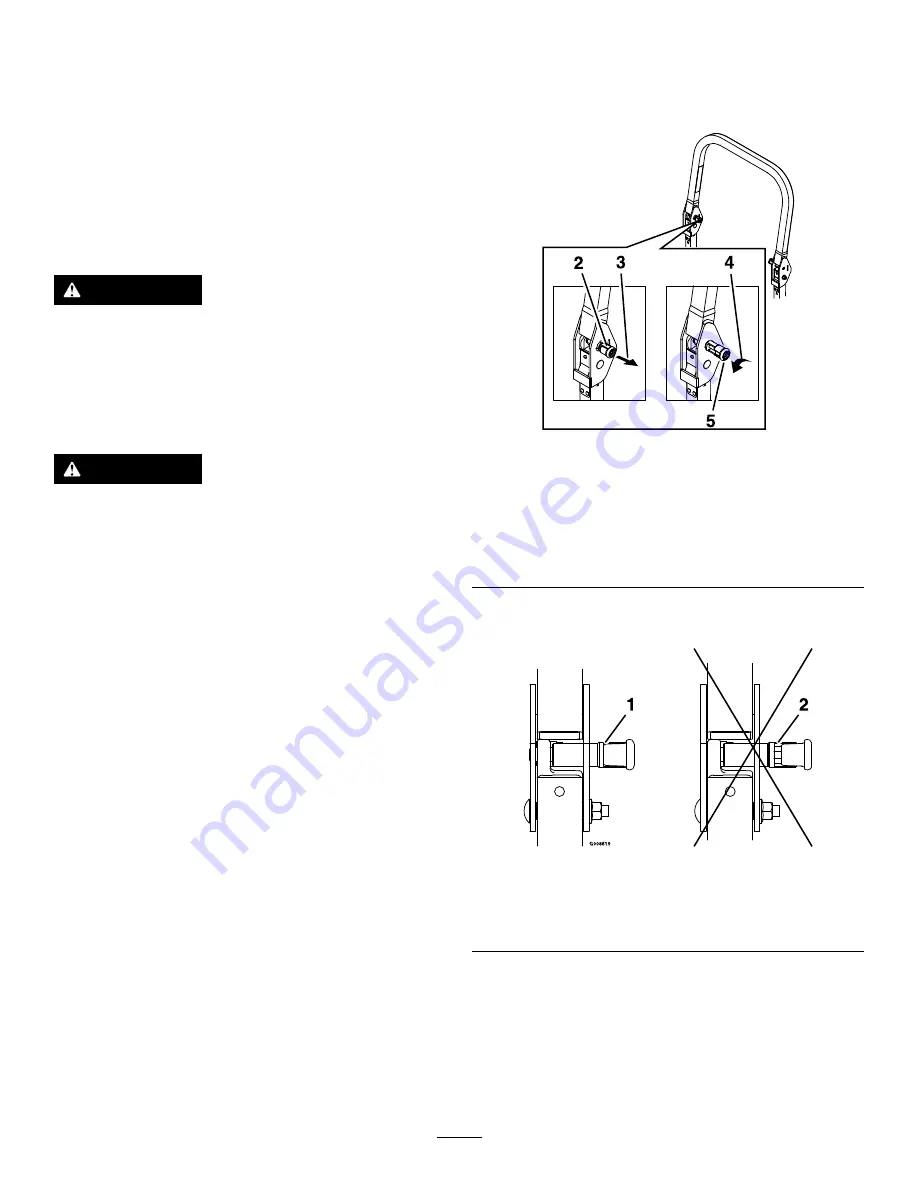

Push on the roll bar and ensure that both pins

are engaged (

g008619

Figure 9

1.

Engaged

2.

Partially engaged—do not

operate the machine with

the ROPS in this position.

19

Summary of Contents for Air Cool Z Master 74090

Page 69: ...g008623 Hydraulic Schematic Rev A 69 ...

Page 72: ......