Jump-Starting the Machine

1.

Check the weak battery for terminal corrosion

(white, green, or blue “snow”).

You must clean it off prior to jump-starting.

Clean and tighten connections as necessary.

CAUTION

Corrosion or loose connections can

cause unwanted electrical voltage spikes

at anytime during the jump-starting

procedure.

Do not attempt to jump-start with loose

or corroded battery terminals; otherwise,

damage may occur to the engine.

DANGER

Jump-starting a weak battery that is

cracked, frozen, has low electrolyte level,

or an open/shorted battery cell, can

cause an explosion, resulting in serious

injury.

Do not jump-start a weak battery if these

conditions exist.

2.

Ensure that the booster is a good and

fully-charged lead acid battery at 12.6 V or

greater. Use properly sized jumper cables (4 to 6

AWG) with short lengths to reduce voltage drop

between systems. Ensure that the cables are

color-coded or labeled for the correct polarity.

CAUTION

Connecting the jumper cables incorrectly

(wrong polarity) can immediately damage

the electrical system.

Be certain of battery-terminal polarity and

jumper-cable polarity when connecting

batteries.

Note:

The following instructions are adapted

from the SAE J1494 Rev. Dec. 2001 –

Battery Booster Cables – Surface Vehicle

Recommended Practice (SAE – Society of

Automotive Engineers).

Important:

Ensure that the vent caps

are tight and level. Place a damp cloth,

if available, over any vent caps on both

batteries. Ensure that the machines do

not touch and that both electrical systems

are shut off and at the same rated system

voltage. These instructions are for negative

ground systems only.

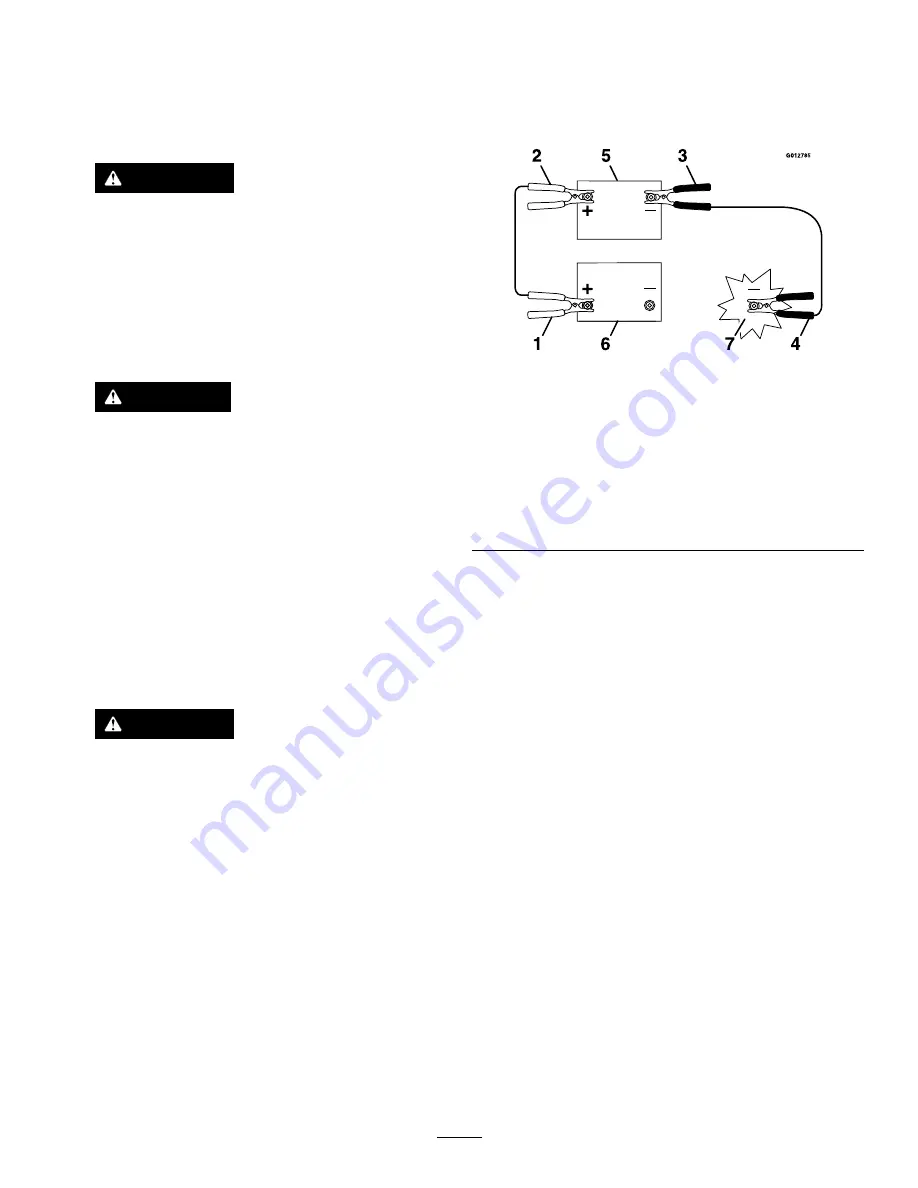

3.

Connect the positive (+) cable to the positive (+)

terminal of the discharged battery that is wired

to the starter or solenoid (

g012785

Figure 52

1.

Positive (+) cable on the discharged battery

2.

Positive (+) cable on the booster battery

3.

Negative (–) cable on the booster battery

4.

Negative (–) cable on the engine block

5.

Booster battery

6.

Discharged battery

7.

Engine block

4.

Connect the other end of the positive cable to

the positive terminal of the booster battery.

5.

Connect the black negative (–) cable to the other

terminal (negative) of the booster battery.

6.

Make the final connection on the engine block

of the stalled machine (not to the negative post)

away from the battery. Stand away from the

machine.

7.

Start the vehicle and remove the cables in the

reverse order of connection (the engine block

(black) connection is the first to disconnect).

48

Summary of Contents for Air Cool Z Master 74090

Page 69: ...g008623 Hydraulic Schematic Rev A 69 ...

Page 72: ......