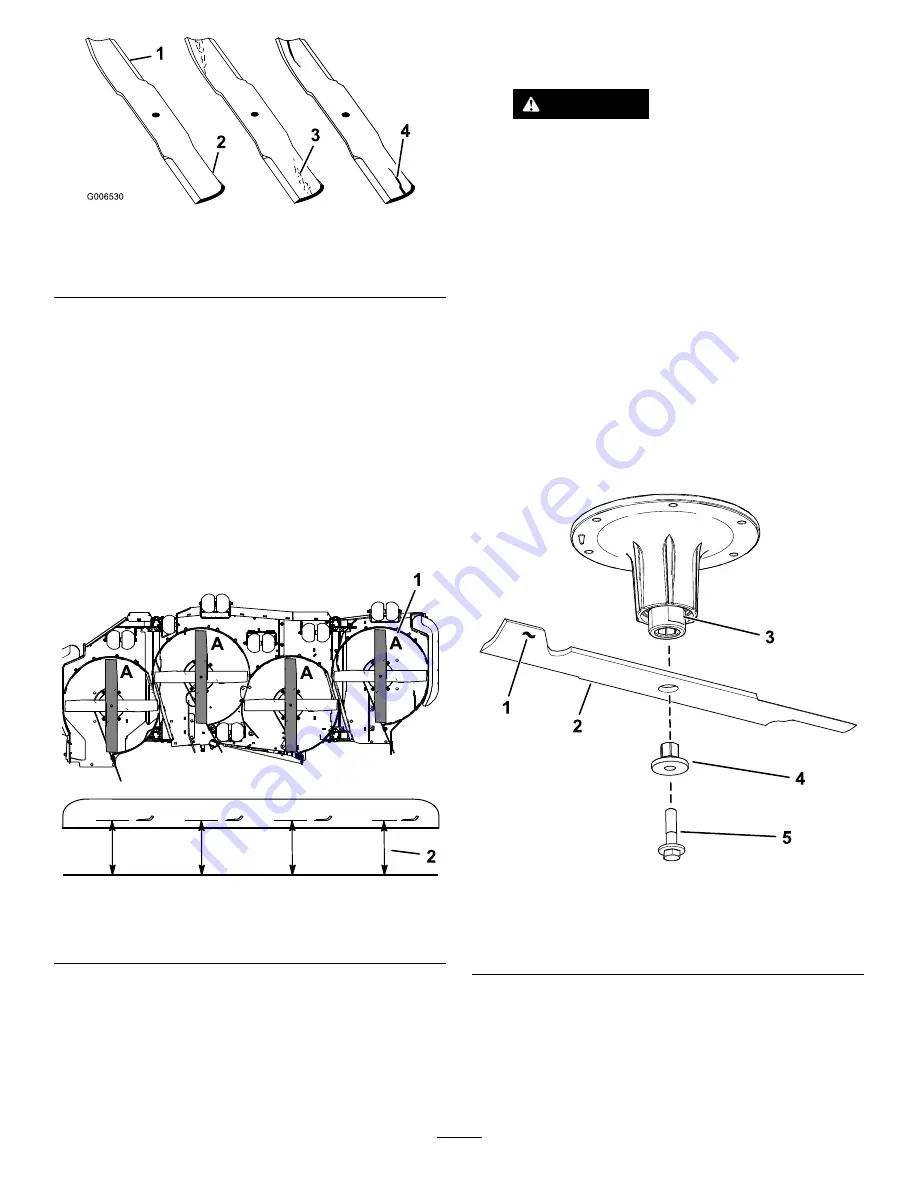

g006530

Figure 74

1.

Cutting edge

3.

Wear/slot forming

2.

Curved area

4.

Crack

Checking for Bent Blades

1.

Disengage the blade-control switch (PTO), move

the motion-control levers to the N

EUTRAL

-

LOCK

position, and engage the parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Rotate the blades until the ends face forward

and backward (

4.

Measure from a level surface to the cutting

edge, position

A

, of the blades (

g243961

Figure 75

1.

Position A

2.

Measure here from the

blade to a hard surface.

5.

Rotate the opposite ends of the blades forward.

6.

Measure from a level surface to the cutting edge

of the blades at the same position as in step

.

Note:

The difference between the dimensions

obtained in steps

and

must not exceed 3

mm (1/8 inch).

Note:

If this dimension exceeds 3 mm (1/8

inch), the blade is bent and must be replaced.

DANGER

A blade that is bent or damaged could

break apart and could seriously injure or

kill you or bystanders.

•

Always replace bent or damaged

blade with a new blade.

•

Never file or create sharp notches in

the edges or surfaces of blade.

Removing the Blades

Replace the blades if they hit a solid object, or if the

blade is out of balance or bent.

1.

Place a wrench on the flat of the spindle shaft or

hold the blade end using a rag or thickly padded

glove.

2.

Remove the blade bolt, bushing, and blade from

the spindle shaft (

).

g295816

Figure 76

1.

Sail area of the blade

4.

Bushing

2.

Blade

5.

Blade bolt

3.

Flat of the spindle shaft

62

Summary of Contents for Air Cool Z Master 74090

Page 69: ...g008623 Hydraulic Schematic Rev A 69 ...

Page 72: ......