Checking the Hydraulic Lines

and Hoses

Daily, check hydraulic lines and hoses for leaks, kinked

lines, loose mounting supports, wear, loose fittings,

weather deterioration, and chemical deterioration. Make

all necessary repairs before operating.

Cutterheads System

Maintenance

Cutterheads Maintenance

Checking Cutterheads Rear Roller

Bearing Adjustment

Service Interval:

Every 50 hours

Important:

It is essential that the cutterheads roller

bearings are kept in good adjustment in order to

ensure maximum working life. If roller end float is

allowed to become excessive, premature bearing

damage will result.

Grip the roller and move from side to side and up and

down. If excessive movement is detected, proceed as

follows:

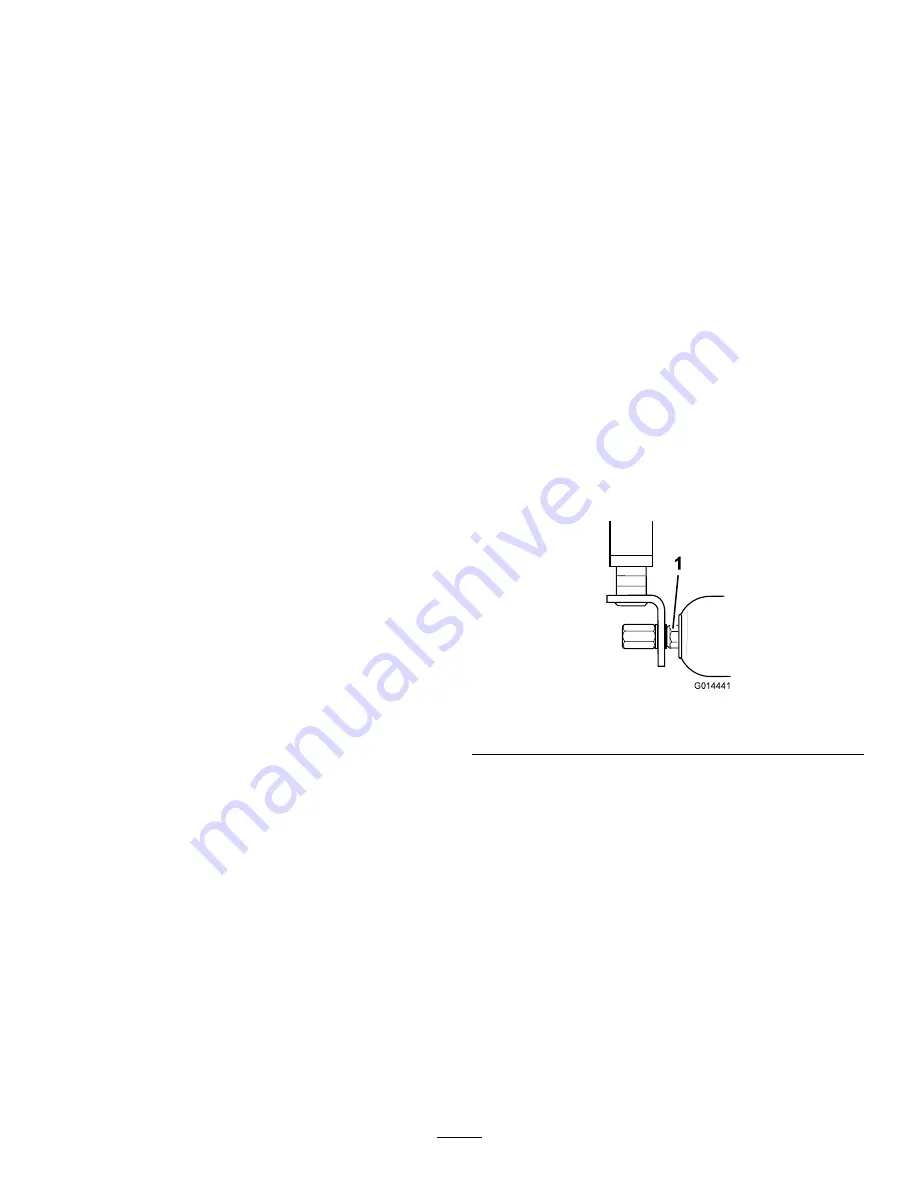

Carefully tighten nuts (Figure 65) at each end of the

roller with the spanner provided, just sufficiently to

remove any end float.

1

G014441

Figure 65

1.

Nuts

Note:

The roller should still rotate freely after

adjustment. Overtightening of nuts (Figure 65) could

lead to premature bearing damage.

Checking Cutterheads Rear Roller

Scraper Wire Tension

Service Interval:

Every 50 hours

It is important that the scraper wires are correctly

tensioned so as to ensure that the correct operation and

maximum working life. Carefully tighten the scraper

wire retaining nuts so as to remove any slack from

the scraper wires then tighten nuts a full four turns to

correctly tension the wire (Figure 66).

46

Summary of Contents for CT2120 30655

Page 55: ...Schematics Showing Beacon Lights Aux Power Connector g014756 55 ...

Page 61: ...Notes 61 ...

Page 62: ...Notes 62 ...