2

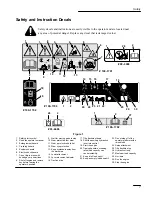

Safety

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with these safety instructions

and always pay attention to the safety alert

symbol, which means CAUTION, WARNING, or

DANGER—“personal safety instruction.” Failure

to comply with the instruction may result in

personal injury or death.

Safe Operating Practices

This product is capable of amputating hands and feet.

Always follow all safety instructions to avoid serious

injury or death.

General Operation

•

Read, understand, and follow all instructions in

the operator’s manual and on the traction unit

before starting. Also, read all attachment

manuals where supplied

•

Allow only responsible adults who are familiar

with the instructions to operate the traction unit.

•

Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes, hearing

protection, and a hard hat are advisable and may

be required by some local ordinances and

insurance regulations.

•

Ensure that the area is clear of other people

before operating the traction unit. Stop the

traction unit if anyone enters the area.

•

Never carry passengers on attachments or on the

traction unit.

•

Always look down and behind before and while

backing.

•

Do not place your feet under the platform.

•

Slow down before turning. Sharp turns on any

terrain may cause loss of control.

•

Never leave a running traction unit unattended.

Always lower the loader arms, stop the engine,

and remove the key before dismounting.

•

Do not exceed the rated operating capacity, as

the traction unit may become unstable which

may result in loss of control.

•

Do not carry a load with the arms raised. Always

carry loads close to the ground. Do not step off

of the platform with the load raised.

•

Do not over-load the attachment and always

keep the load level when raising the loader arms.

Logs, boards, and other items could roll down

the loader arms, injuring you.

•

Never jerk the control levers; use a steady

motion.

•

Keep your hands, feet, hair, and loose clothing

away from any moving parts.

•

Operate only in daylight or good artificial light.

•

Do not operate the traction unit while under the

influence of alcohol or drugs.

•

Watch for traffic when operating near or crossing

roadways.

•

Use extra care when loading or unloading the

traction unit onto a trailer or truck.

•

Do not touch parts which may be hot from

operation. Allow them to cool before attempting

to maintain, adjust, or service.

Slope Operation

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra caution.

Summary of Contents for Dingo 322

Page 8: ...Safety 6 Slope Chart...