Hydraulic System

Maintenance

Hydraulic System Safety

•

Seek immediate medical attention if fluid is injected

into skin. Injected fluid must be surgically removed

within a few hours by a doctor.

•

Ensure that all hydraulic-fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

•

Keep your body and hands away from pinhole

leaks or nozzles that eject high-pressure hydraulic

fluid.

•

Use cardboard or paper to find hydraulic leaks.

•

Safely relieve all pressure in the hydraulic system

before performing any work on the hydraulic

system.

Hydraulic System

Specifications

Hydraulic Fluid Type:

Toro

®

HYPR-OIL

™

500

hydraulic fluid

Hydraulic System Fluid Capacity:

4.7 L (159 fl oz)

Important:

Use the fluid specified. Other fluids

could damage the system.

Checking the Hydraulic

Fluid

Service Interval:

After the first 8 hours

Every 50 hours

Note:

Check the hydraulic-fluid level when the fluid

is cold.

1.

Park the machine on a level surface, disengage

the PTO, and engage the parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Wait for the machine to cool.

4.

Clean the area around the cap and the filler neck

of the hydraulic tank (

g301336

Figure 77

1.

Hydraulic-tank cap

2.

Cold fluid level

5.

Remove the cap from the filler neck (

Note:

Look inside to check the fluid level in

the reservoir.

6.

Add fluid to the reservoir until it reaches the

reaches the minimum cold fill level.

7.

Install the cap on the filler neck.

Replacing the Hydraulic

Fluid and Filters

Service Interval:

After the first 50 hours

Every 500 hours/Yearly (whichever comes

first)—Change the hydraulic filters and hydraulic

fluid.

Change the hydraulic fluid more frequently in severe

conditions or in a hot operating climate. Contact

your Authorized Service Dealer for a hydraulic kit to

replace the hydraulic filters.

WARNING

Hot hydraulic fluid can cause severe burns.

Allow the hydraulic fluid to cool before

performing any maintenance on the hydraulic

system.

1.

Park the machine on a level surface, disengage

the PTO, and engage the parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Remove the fuel tank; refer to

.

47

Summary of Contents for GrandStand 72504TE

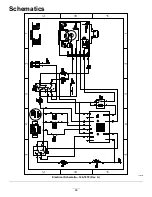

Page 58: ...Schematics g302050 Electrical Schematic 140 1878 Rev A 58 ...

Page 59: ...Notes ...