4.

Remove the hydraulic-reservoir cap.

5.

Locate the drain plug in the bottom of each

transmission and place a drain pan under the

plugs (

g268090

Figure 78

1.

Drain plug

2.

Hydraulic filter

6.

Remove the drain plugs.

7.

Allow the hydraulic fluid to fully drain from the

machine.

8.

Remove the hydraulic filter cap and filter from

each transmission.

9.

Install new hydraulic filters with the spring side

facing out and install the filter caps.

10.

Install the drain plugs and torque to 22 to 27

N∙m (16 to 20 ft-lb).

11.

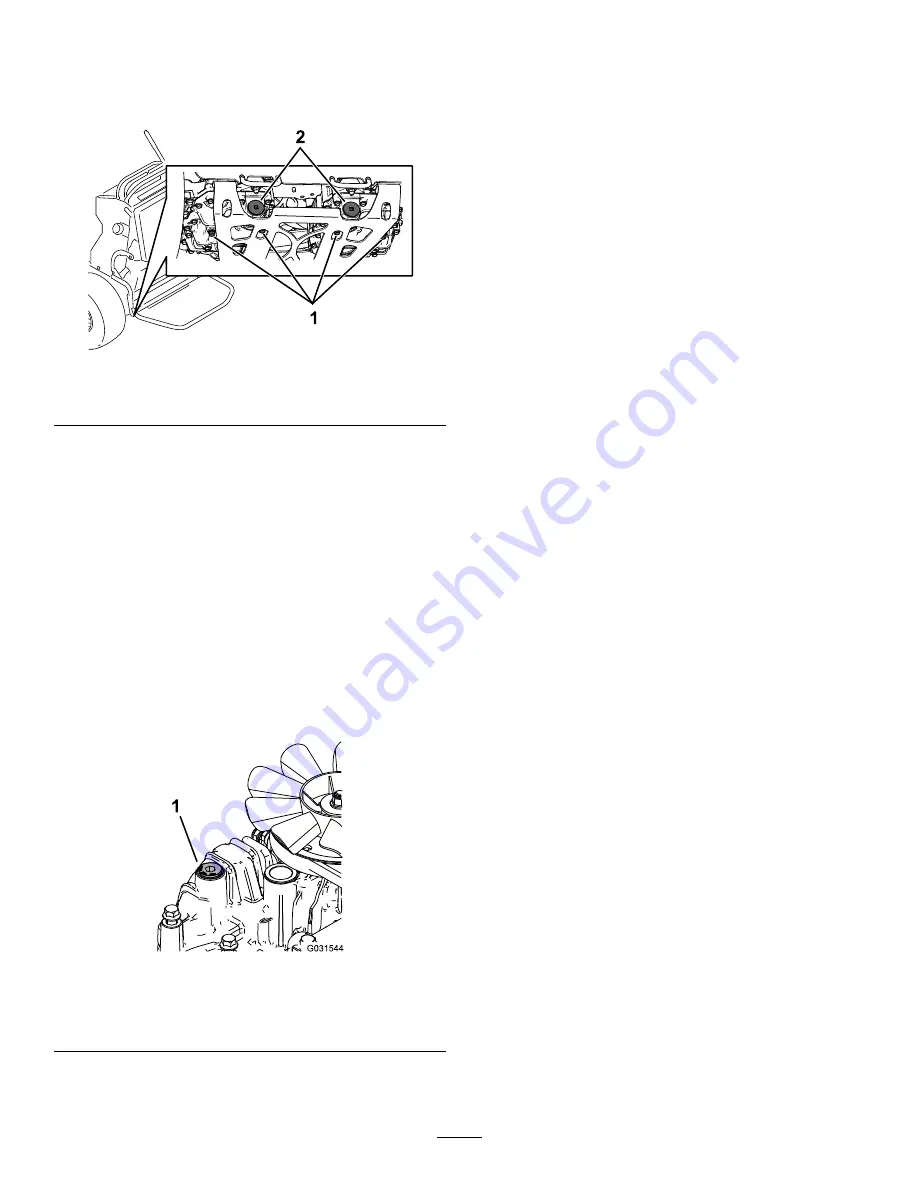

Loosen the vent plug in each transmission so

that it is loose and wobbles (

Note:

This allows air to escape the hydraulic

system as you add hydraulic fluid.

g031544

Figure 79

Left transmission shown

1.

Vent plug

12.

Slowly add fluid to the hydraulic tank until it

starts to come out 1 of the vent plugs.

Important:

Use the fluid specified in

Hydraulic System Specifications (page 47)

or

equivalent. Other fluids could cause system

damage.

Important:

Monitor the level of fluid in the

hydraulic tank so that you do not overfill it.

13.

Tighten the vent plugs.

14.

Install the hydraulic-tank cap.

15.

Install the fuel tank.

16.

Start the engine and let it run for about 2 minutes

to purge air from the system.

17.

Shut off the engine and check for leaks.

Note:

If 1 or both wheels do not drive, refer to

Bleeding the Hydraulic System (page 48)

.

Bleeding the Hydraulic

System

The traction system is self-bleeding, however, it may

be necessary to bleed the system if fluid is changed

or after work is performed on the system.

1.

Park the machine on a level surface, disengage

the PTO, and engage the parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Raise the rear of the machine onto jack stands

high enough to raise the drive wheels off the

ground.

4.

Start the engine and move the throttle control to

the idle position.

Note:

If the drive wheel does not rotate, assist

the purging of the system by carefully rotating

the tire in the forward direction.

5.

Check the hydraulic fluid level as it drops, and

add fluid as required to maintain the proper level.

6.

Repeat this procedure for the opposite wheel.

48

Summary of Contents for GrandStand 72504TE

Page 58: ...Schematics g302050 Electrical Schematic 140 1878 Rev A 58 ...

Page 59: ...Notes ...