23

MAINTENANCE

CAUTION

Before servicing or making adjustments to the

machine, stop engine and remove key from

the switch.

ENGINE CARE

The Engine Manual supplied with your Greens Aerator

provides the maintenance procedures for service of

the air cleaner, oil requirements, ignition components,

etc.

Note:

If Greens Aerator is to be operated at altitudes of

3000 feet or above sea level, it may require a high

altitude carburetor main jet. Order Part No. 8055537

from your Authorized Briggs & Stratton Service Dealer.

CHANGING HYDRAULIC SYSTEM OIL

The hydraulic system oil must be changed immediately

when any contamination, sludge, water or

condensation appears.

1.

Remove tines from tine blocks and lower coring

head; refer to Install Tines.

2.

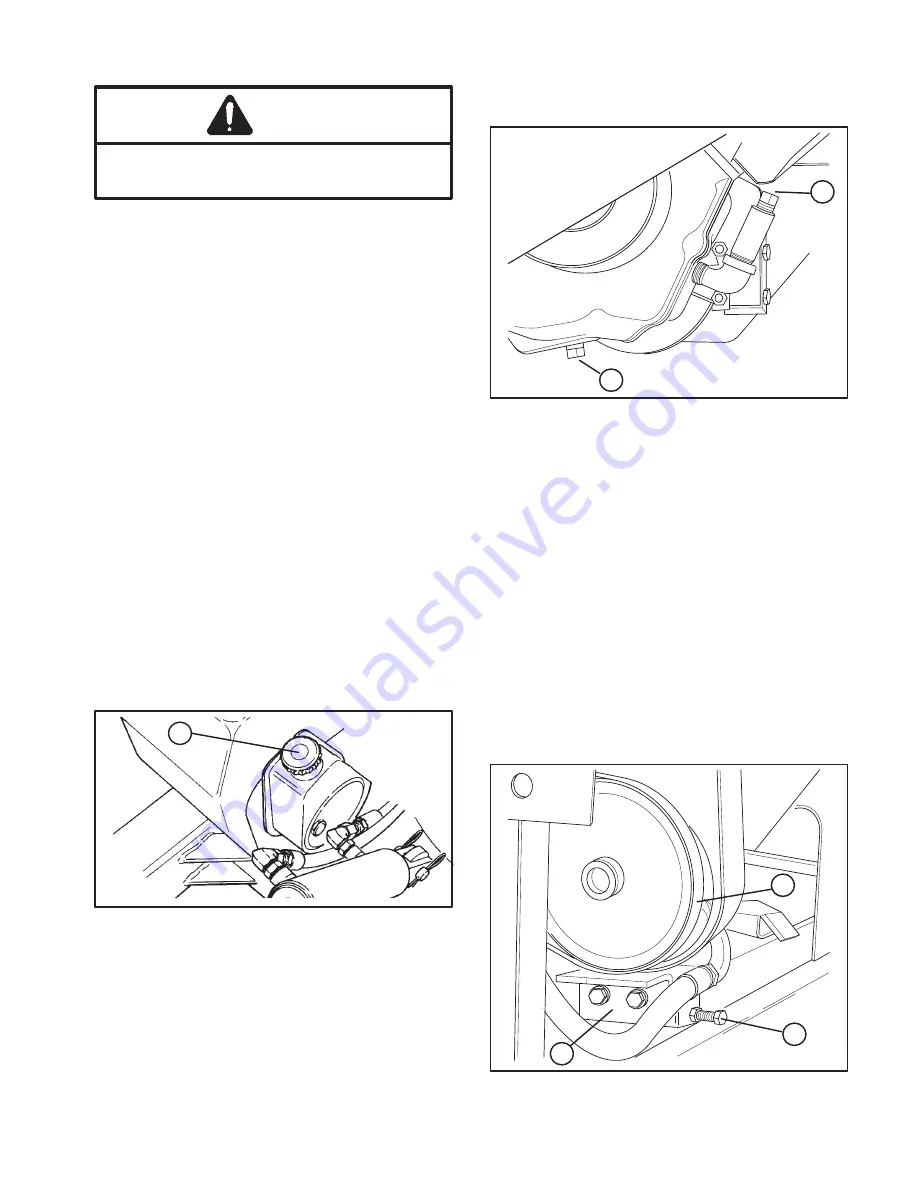

Position a drain pan under chassis below pump

assembly (Fig. 28).

3.

Remove hose clamp securing return hose to

pump. Disconnect hose from pump allowing oil to flow

into drain pan.

4.

Connect return hose to pump and secure with

hose clamp.

1. Pump reservoir

Figure 28

1

5.

Fill pump reservoir; refer to checking Hydraulic

System Fluid.

6.

Check all connections for possible leaks.

CHANGE TRANSAXLE OIL

Each year oil in transaxle must be changed. If possible

run machine just before changing oil. Warm oil flows

more freely and carries more contaminants than cold

oil.

1.

Place a drain pan below drain plug on axle. Clean

area around drain plug (Fig. 29).

1. Drain plug

2. Fill plug

Figure 29

1

2

2.

Remove drain plug and allow oil to flow into drain

pan. After oil is drained, reinstall drain plug.

3.

Remove fill plug (Fig. 29) and pour approx. 64 oz.

of SAE E.P. 90 wt. oil into extension tube. Stop when oil

level reaches top of tube.

4

. To check oil level in the future: remove plug, and

add oil as required to bring level to top of tube.

BELT ADJUSTMENTS

Make sure belts are properly tensioned to assure

correct operation of unit and unnecessary wear. Check

all belts midway in the span of the belt.

1.

The belt tension on the hydraulic pump (Fig. 30)

must have a maximum deflection of 5/32 of an inch with

a 2 to 3 pound load applied.

1. Hydraulic pump belt

2. Pump support bracket

3. Adjusting screw

Figure 30

1

3

2