Greensmaster 3320/3420

Hydraulic System

Page 5 -- 67

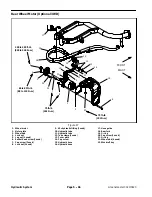

Rear Wheel Motor (Optional 3WD) Removal (Fig. 47)

1. Park machine on a level surface, engage the parking

brake, lower the cutting units and stop the engine. Re-

move key from the ignition switch.

CAUTION

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components in

this section.

2. Loosen, but do not remove, rear wheel lug nuts (item

5) and lock nut (item 4). Loosen lock nut at least two (2)

turns.

3. Chock both front wheels to prevent the machine from

moving. Lift rear wheel off the ground using a jack and

place appropriate jack stands beneath the frame to sup-

port the machine.

4. Remove lug nuts and rear wheel assembly.

IMPORTANT: DO NOT hit wheel hub, wheel hub

puller or wheel motor with a hammer during wheel

hub removal or installation. Hammering may cause

damage to the wheel motor.

5. Use wheel hub puller (see Special Tools in this chap-

ter) to loosen wheel hub from rear wheel motor.

6. Remove lock nut and wheel hub from rear wheel mo-

tor. Locate and retrieve woodruff key (item 23).

7. Thoroughly clean hydraulic tube ends and fittings on

rear wheel motor to prevent hydraulic system contami-

nation.

8. Label hydraulic connections at rear wheel motor for

assembly purposes.

9. Disconnect hydraulic tubes from fittings on wheel

motor. Allow lines to drain into a suitable container.

10.Put clean caps or plugs on disconnected tubes and

fittings to prevent contamination.

11. Support wheel motor to prevent it from falling. Re-

move two (2) cap screws (item 7), two (2) socket head

screws (item 6) and two (2) flange nuts (item 8) that se-

cure wheel motor to rear fork. Remove rear wheel motor

and motor plate (item 2) from machine.

12.If fitting removal from wheel motor is necessary,

mark fitting orientation to allow correct assembly. Re-

move hydraulic fittings and O--rings from motor. Discard

removed O--rings.

Rear Wheel Motor (Optional 3WD) Installation (Fig.

47)

1. If fittings were removed from rear wheel motor, lubri-

cate and place new O--rings onto motor fittings. Install

fittings into motor openings making sure that fitting ori-

entation is as noted during removal. Tighten fittings (see

Hydraulic Fitting Installation in the General Information

section of this chapter).

2. Place motor plate (item 2) on rear wheel motor and

position motor to rear fork. Secure wheel motor to rear

fork with two (2) cap screws (item 7), two (2) socket head

screws (item 6) and two (2) flange nuts (item 8). Torque

fasteners to

75 ft--lb (101 N--m)

.

3. Remove caps from disconnected hydraulic tubes.

4. Lubricate and position new O--rings to fittings on rear

wheel motor. Use labels placed during the removal pro-

cess to properly install hydraulic tubes to wheel motor fit-

tings (see Hydraulic Hose and Tube Installation in the

General Information section of this chapter).

5. Thoroughly clean wheel motor shaft and wheel hub

taper.

6. Install woodruff key into the wheel motor shaft key-

slot. Align wheel hub with woodruff key and slide wheel

hub onto motor shaft. Secure hub with lock nut.

7. Install rear wheel to machine and secure with four (4)

lug nuts.

Failure to maintain proper wheel lug nut and

wheel hub lock nut torque could result in failure

or loss of wheel and may result in personal injury.

WARNING

8. Lower machine to ground. Torque lock nut from

250

to 400 ft--lb (339 to 540 N--m)

and wheel lug nuts from

65 to 85 ft--lb (89 to 115 N--m)

.

9. Check oil level in hydraulic reservoir and add correct

oil if necessary.

10.Follow Hydraulic System Start--up procedures (see

Hydraulic System Start--up in this section).

Hy

draulic

Sy

st

em

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...