Greensmaster 3320/3420

Hydraulic System

Page 5 -- 85

5. Remove hose assemblies and O--rings from hydrau-

lic fittings at the cylinder. Allow hoses to drain into a suit-

able container.

6. Put clean caps or plugs on disconnected hoses and

fittings to prevent contamination.

7. Support steering cylinder to prevent it from falling.

8. Remove jam nuts that secure cylinder ball joints to

frame and rear fork assembly.

9. Separate cylinder ball joints from frame and rear

fork. Remove steering cylinder from machine. Locate

and retrieve cylinder spacer (item 10).

10.If necessary, remove hydraulic fittings from steering

cylinder and discard O--rings.

11. If necessary, remove ball joints from steering cylin-

der. Discard removed ball joints.

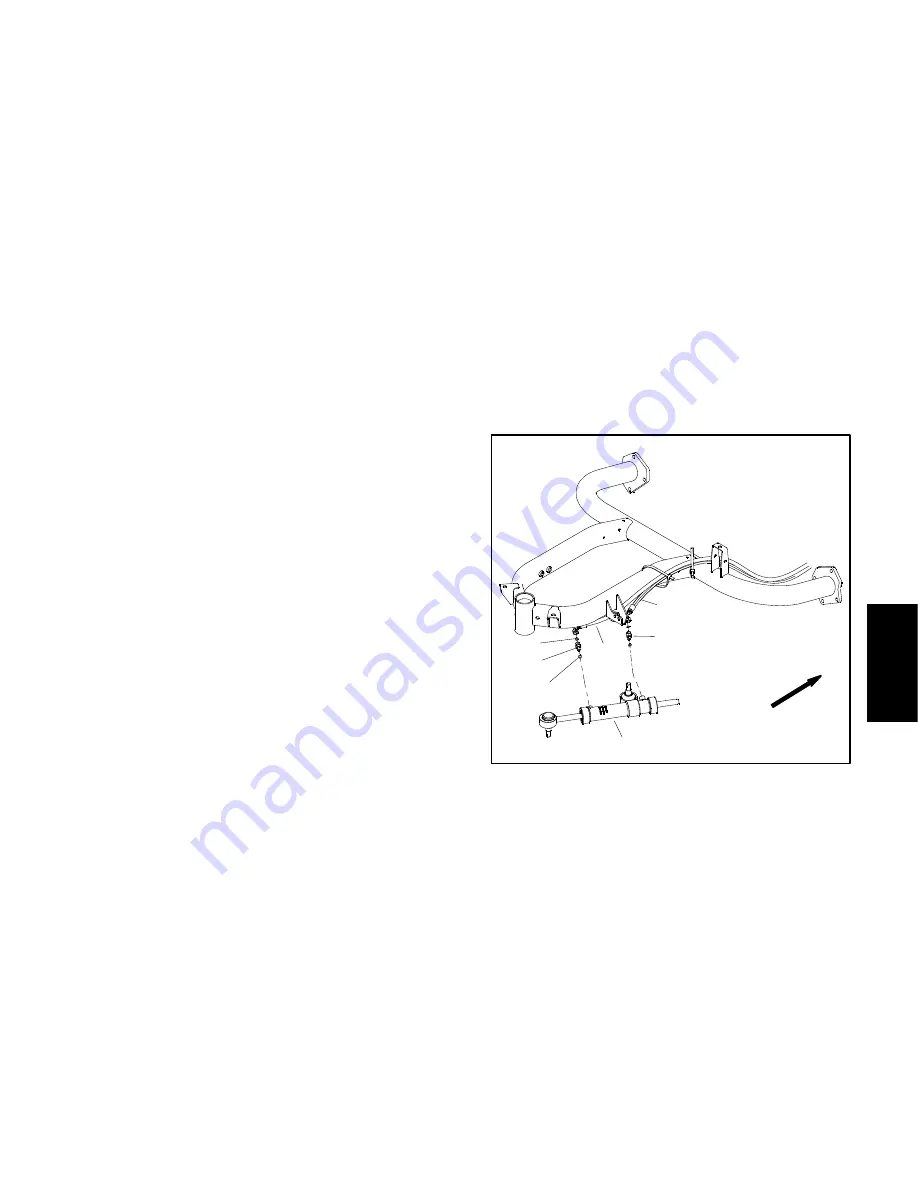

Installation (Fig. 56)

1. If ball joints were removed from steering cylinder,

press new ball joints into steering cylinder and secure

with retaining rings.

2. If fittings were removed from steering cylinder, lubri-

cate and place new O--rings onto fittings. Install fittings

into cylinder port openings. Tighten fittings (see Hydrau-

lic Fitting Installation in the General Information section

of this chapter).

3. Thoroughly clean tapered surfaces of steering cylin-

der ball joints and cylinder attachment bores on ma-

chine.

4. Place cylinder spacer (item 10) onto cylinder barrel

ball joint.

5. Insert ball joints of cylinder into attachment points on

frame and rear fork assembly.

6. Secure both steering cylinder ball joints to machine

with two (2) jam nuts (item 4). Install first jam nut and

torque from

60 to 80 ft--lb (82 to 108 N--m)

. Then, while

holding first jam nut with wrench, tighten second jam nut

and torque from

60 to 80 ft--lb (82 to 108 N--m)

.

7. Remove caps and plugs from disconnected hoses

and fittings.

8. Lubricate new O--rings and connect hydraulic hoses

to steering cylinder (Fig. 57). Tighten hose connections

(see Hydraulic Hose and Tube Installation in the Gener-

al Information section of this chapter).

9. Lower and secure tank mount plate assembly (hy-

draulic reservoir, fuel tank and tank mount plate) (see

Tank Mount Plate Assembly in the Service and Repairs

section of Chapter 7 -- Chassis).

10.Check fluid level in hydraulic oil reservoir and adjust

as required.

11. After assembly is completed, operate steering cylin-

der to verify that hydraulic hoses and fittings are not con-

tacted by anything and that there are no leaks. Also,

make sure that a clockwise rotation of the steering wheel

turns the rear wheel for a right turn.

1. Steering cylinder

2. Hyd fitting (2 used)

3. Hyd hose

4. Hyd hose

5. O--ring

6. O--ring

Figure 57

6

5

4

3

2

2

1

FRONT

Hy

draulic

Sy

st

em

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...