Greensmaster 3320/3420

Page 6 -- 58

Electrical System

Hydraulic Solenoid Valve Coils

The Greensmaster hydraulic control manifolds use sev-

eral hydraulic solenoid valve coils for system control.

The lift manifold includes four (4) solenoid valves. On

machines equipped with the optional Turf Guardian

TM

Leak Detector, the leak detector manifold includes a

single solenoid valve. When the solenoid coils are ener-

gized, hydraulic valve shift occurs to control hydraulic

circuit flow. Testing of the coils can be done with the coil

installed on the hydraulic valve.

Testing

NOTE:

Before disconnecting and testing solenoid

valve coils, test the TEC controller outputs with the Hand

Held Diagnostic Display (see Hand Held Diagnostic Dis-

play in the Troubleshooting section of this chapter) or

InfoCenter Display (see InfoCenter Display in this

chapter). If the Diagnostic or InfoCenter Display verifies

that the TEC outputs

are

functioning correctly, consider

that a problem with the solenoid valve coil or circuit wir-

ing may exist. An open or shorted controller output (e.g.

a failed solenoid valve coil, an unplugged connector or

a broken wire) cannot be detected with the Diagnostic

or InfoCenter Display. Conversely, if the Diagnostic or

InfoCenter Display verifies that the TEC outputs

are not

functioning correctly, consider that a problem with con-

troller inputs, controller fuses or the TEC controller may

exist.

1. Park machine on level surface, lower cutting units,

stop engine, apply parking brake and remove key from

ignition switch.

2. Determine solenoid coil(s) that are to be tested and

locate coil on correct hydraulic manifold:

A. Remove right side cover next to operator seat to

allow access to lift control manifold.

B. To gain access to leak detector manifold, see

Leak Detector Solenoid Valve Assembly in the Ser-

vice and Repairs section of Chapter 5 -- Hydraulic

System.

3. Disconnect harness electrical connector from hy-

draulic solenoid valve coil that is to be tested (Fig. 72 or

73).

NOTE:

Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter may display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from the measured value of the solenoid coil being

testing.

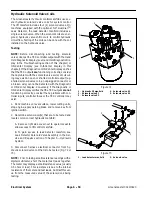

1. Hydraulic lift manifold

2. Solenoid valve S1

3. Solenoid valve S2

4. Solenoid valve S3

5. Solenoid valve S4

Figure 72

2

4

5

3

1

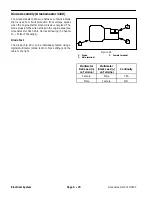

1. Leak detector manifold

2. Solenoid valve

Figure 73

2

1

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...