Greensmaster 3320/3420

DPA Cutting Units

Page 8 -- 21

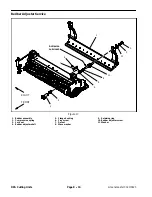

Cutting Reel Assembly Removal (Fig. 22)

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when removing the cutting reel.

1. Position machine on a clean and level surface, lower

cutting units, stop engine, engage parking brake and re-

move key from the ignition switch.

2. Remove the cutting unit from the machine and place

cutting unit on a flat work area.

3. If cutting unit is equipped with an optional groomer or

rear roller brush, remove drive components for those

options from cutting unit. See Service and Repairs sec-

tion of Chapter 9 -- Groomer for information on groomer.

See Rear Roller Brush in this section for information on

rear roller brush.

4. Remove two (2) cap screws and nuts that secure

weight (item 10) to the RH side plate. Remove weight

assembly (items 10 and 20) from the cutting unit. Re-

move and discard O--ring from weight.

5. If bearings or seals are to be removed from cutting

reel, put a block of wood between the cutting reel blades

to prevent the reel from rotating. Loosen bearing lock

nut (RH threads) and reel nut (LH threads) to allow easi-

er removal after reel assembly is removed from cutting

unit (Fig. 23).

6. Remove the bedbar pivot bolt and washers from the

LH side plate. Note location of plastic and steel washers

for assembly purposes (see Bedbar Removal in this

section).

7. Loosen fasteners that secure front and rear rollers to

LH side plate (see Front Roller Removal and Rear Roller

Removal in this section).

8. Remove washer head screws (item 3) that secure

crosslink (item 15) to pitch arms. Remove crosslink.

9. Support cutting reel to keep it from shifting or falling.

10.Remove shoulder bolts (item 4) and flange nuts (item

5) that secure the LH side plate to the cutting unit cross-

member. Remove the LH side plate from the reel shaft,

rollers, bedbar and cutting unit crossmember. Locate

and remove flat wire spring (item 14). Remove pitch arm

(item 7) from side plate.

11. Carefully slide the cutting reel assembly (with

flocked seals, reel bearings, bearing lock screw and reel

nut) from the RH side plate.

1. Cutting reel

2. Flocked seal (2 used)

3. Bearing (2 used)

4. Plug

5. Bearing lock screw

6. Reel nut (LH threads)

7. Reel groove location

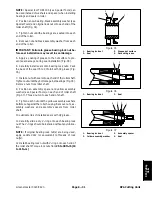

Figure 23

1

2

3

4

5

3

2

7

6

(Right Hand Threads)

90 to 110 ft--lb

(123 to 149 N--m)

90 to 110 ft--lb

(123 to 149 N--m)

(Left Hand Threads)

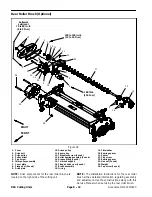

Cutting Reel Assembly Installation (Fig. 22)

1. Thoroughly clean side plates and other cutting unit

components. Inspect side plates and pitch arms for

wear or damage and replace components if needed.

2. Make sure that flocked seals, reel bearings, bearing

lock screw and reel nut are properly positioned on cut-

ting reel (see Reel Assembly Service in this section). Ap-

ply thin coat of grease to outside of bearings on cutting

reel to ease reel installation.

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when installing the cutting reel.

3. Position the cutting unit on a flat work area. The roll-

ers, bedbar and cutting unit crossmember should be at-

tached to RH side plate. Make sure that pitch arm (item

7) is fitted to RH side plate.

4. Carefully slide the cutting reel assembly (with

flocked seals, reel bearings, bearing lock screw and reel

nut) into the RH side plate. Make sure that bearing is ful-

ly seated into side plate.

5. Place flat wire spring into bearing bore of LH side

plate. Carefully slide the LH side plate with pitch arm

onto the cutting reel assembly, front roller and rear roller.

Make sure that side plate is fully seated onto bearing on

reel shaft.

DP

A

Cutt

in

g

Un

its

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...