Greensmaster 3320/3420

Hydraulic System

Page 5 -- 39

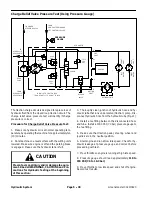

The lower cutting units relief valve (RV) pressure test

should be performed to make sure that the relief pres-

sure for lowering the cutting units is correct.

Procedure for Lower Cutting Units Relief Valve (RV)

Pressure Test:

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately ten

(10) minutes.

2. Park machine on a level surface with the cutting units

lowered. Make sure engine is off and the parking brake

is engaged. Make sure the hydraulic tank is full.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

NOTE:

The lower cutting units relief valve is in series

with the traction charge relief valve. Charge relief pres-

sure will affect the lower cutting units relief pressure.

3. Measure and record charge relief valve pressure

(see Charge Relief Valve Pressure Test in this section).

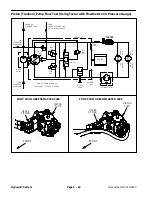

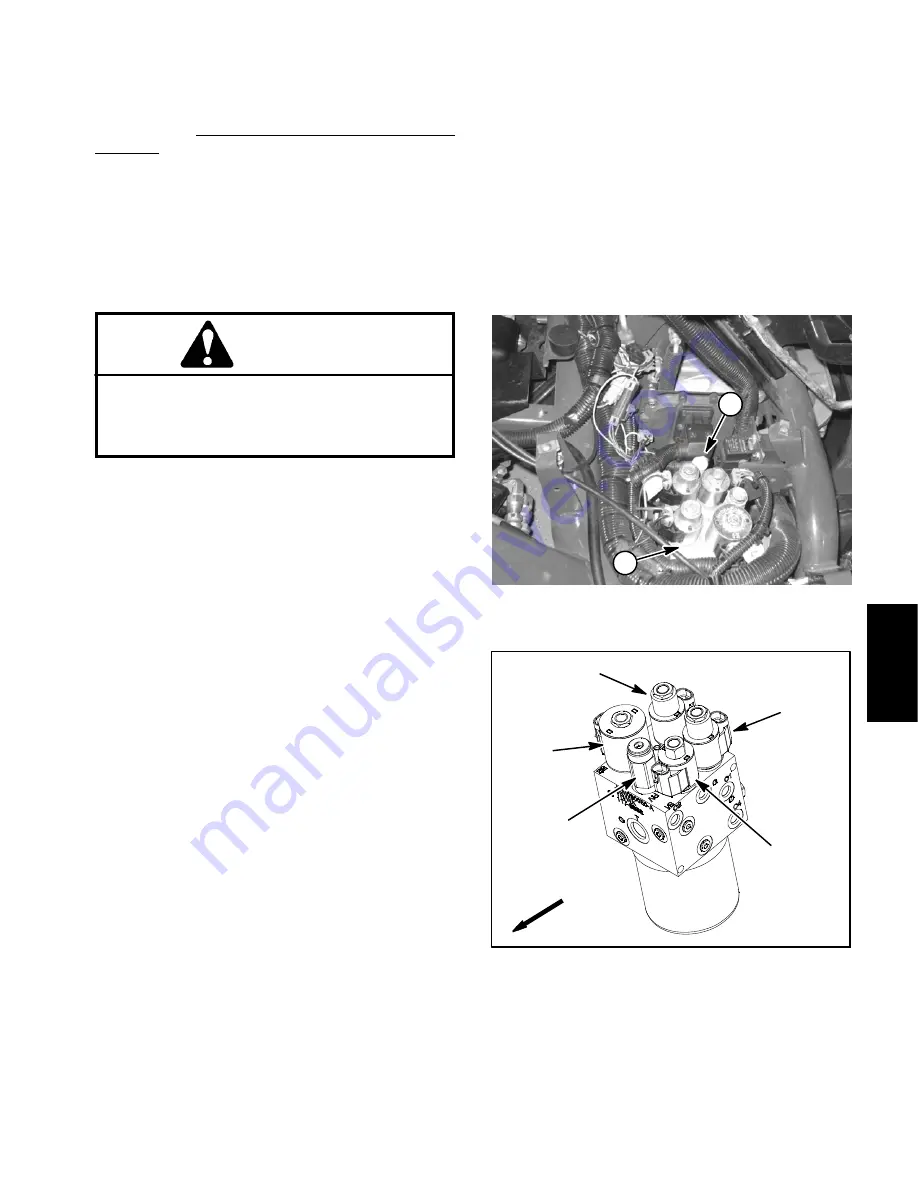

4. Remove right side cover next to operator seat to al-

low access to lift control manifold.

5. Install 1000 PSI (70 bar) pressure gauge with hy-

draulic hose attached to lift control manifold test port (G)

(Fig. 23).

6. After installing pressure gauge, start engine and run

at low idle speed. Check for hydraulic leakage and cor-

rect before proceeding with test.

7. Move throttle so engine is running at high idle speed.

NOTE:

The lower cutting units function is electrically

timed and automatically turns off after approximately

three (3) seconds. While performing this hydraulic test,

if relief pressure cannot be determined within the LOW-

ER function three (3) second timeframe, repeat this test

procedure.

8. Watch pressure gauge carefully while moving the

joystick to LOWER and note pressure that relief valve

opens. Release joystick, move throttle to low idle speed

and shut off engine. Record test results.

9. The lower cutting units relief pressure should be

approximately

400 PSI (27.6 bar) higher than charge

relief pressure

(e.g. if charge relief valve pressure is

125 PSI (8.6 bar), the lower relief valve pressure should

be approximately 525 PSI (36.2 bar)).

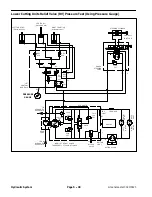

10.If the lower relief valve pressure is incorrect, adjust

lower cutting units relief valve on lift control manifold

(Fig. 24) (see Adjust Manifold Relief Valves in the Ad-

justments section of this Chapter). Retest relief valve

pressure after adjustment is performed.

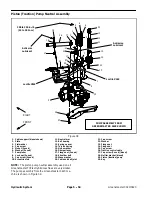

NOTE:

The steering/lift circuit relief valve pressure can

also be measured with pressure gauge positioned as

described in this test (see Steering/Lift Relief Valve

Pressure Test in this section).

11. When testing is complete, disconnect pressure

gauge from lift control manifold test port. Install dust cap

to test port fitting. Install right side cover.

1. Lift control manifold

2. Test port

Figure 23

2

1

Figure 24

FRONT

S3

S1

S4

RELIEF

VALVE (RV)

S2

LIFT CONTROL

MANIFOLD

Hy

draulic

Sy

st

em

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...