Greensmaster 3320/3420

Hydraulic System

Page 5 -- 43

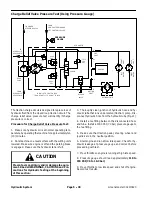

NOTE:

This steering test procedure will be affected by

incorrect rear tire pressure, binding in the hydraulic

steering cylinder, extra weight on the vehicle and/or

binding of the steering fork assembly. Make sure that

these items are checked before proceeding with any hy-

draulic testing procedure.

Procedure for Power Steering Valve Test:

1. Make sure the hydraulic tank is full.

2. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately ten

(10) minutes.

3. Perform the Steering/Lift Relief Valve Pressure and

Steering/Lift Circuit Gear Pump Flow Tests to make sure

that relief valve and gear pump are functioning correctly

(see Steering/Lift Relief Valve Pressure and Steering/

Lift Circuit Gear Pump Flow Tests in this section).

4. Drive machine slowly in a figure eight on a flat level

surface.

A. There should be no shaking or vibration in the

steering wheel or rear wheel.

B. Steering wheel movements should be followed

immediately

by a corresponding rear wheel move-

ment

without

the steering wheel continuing to turn.

5. Stop the unit with the engine running. Turn steering

wheel with small quick movements in both directions.

Let go of the steering wheel after each movement.

A. The steering wheel must go back immediately to

the neutral position.

B. The steering wheel should

not

continue to turn.

NOTE:

The steering wheel must be able to turn with no

more than

45 in--lb (5.1 N--m)

of torque.

6. If either of these performance tests indicate a steer-

ing problem, determine if the steering cylinder is faulty

using the following procedure.

A. Park machine on a level surface with the cutting

units lowered and off. Make sure engine is off and the

parking brake is engaged.

B. Turn the steering wheel all the way to the left

(counterclockwise) so the steering cylinder rod is ful-

ly extended.

C. Turn engine off.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

D. Read Precautions for Hydraulic Testing.

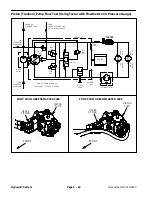

E. Remove hydraulic hose from the fitting on the ball

joint end of the steering cylinder (Fig. 26). Plug the

end of the hose.

F. With the engine off, continue turning the steering

wheel to the left (counterclockwise) with the steering

cylinder fully extended. Observe the open fitting on

the steering cylinder as the steering wheel is turned.

If oil comes out of the fitting while turning the steering

wheel to the left, the steering cylinder has internal

leakage and must be repaired or replaced.

G. When steering cylinder testing is completed, re-

move plug from the hydraulic hose. Connect hose to

the steering cylinder fitting.

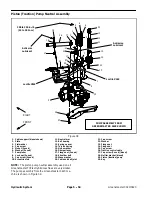

7. If steering problem exists and steering cylinder

tested acceptably, power steering valve requires ser-

vice (see Power Steering Valve and Power Steering

Valve Service in the Service and Repairs section of this

chapter).

Figure 26

1

2

1. Steering cylinder

2. Ball joint end hose

Hy

draulic

Sy

st

em

Summary of Contents for Greensmaster 3420 TriFlex

Page 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Page 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Page 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Page 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Page 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Page 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 347: ...Page 10 9 This page is intentionally blank ...

Page 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Page 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Page 360: ...Page 10 22 This page is intentionally blank ...