Greensmaster Flex 1800/1820/2100/2120

Page 3

−

11

Engine

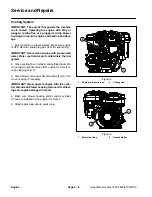

Engine Coupler Sleeve

The coupler sleeve used on Greensmaster Flex ma-

chines allows a positive coupling between the engine

and transmission while also providing vibration damping

and quiet operation. The outer surface of the coupler

sleeve includes a series of curved lines that can be used

to gauge the condition of the internal coupler cogs that

are used to connect the engine and transmission cou-

plers.

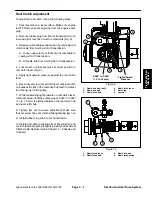

When the coupler sleeve is new, the center line on the

outer surface of the sleeve is basically straight while the

lines above and below are curved in different directions

(Fig. 9). As the coupler wears with normal machine use,

the curved lines may visually straighten indicated that

the coupler has distorted. When removed from the ma-

chine, the inner cogs of a used coupler may exhibit some

offset as shown in Figure 10. This type of offset will gen-

erally not impact normal machine operation. The cog

offset can be 0.250” (6.4 mm) before coupler replace-

ment is necessary.

If a coupler sleeve has torn or missing cogs, the coupler

should be replaced.

Figure 8

1. Engine

2. Key

3. Engine

coupler

4. Set screw (2 used)

5. Coupler

sleeve

2

1

3

4

5

65 in

−

lb

(7.3 N

−

m)

Figure 9

Figure 10

Engine

Summary of Contents for Greensmaster Flex 1820

Page 4: ...NOTES _...

Page 6: ...Greensmaster Flex 1800 1820 2100 2120 This page is intentionally blank...

Page 8: ...Greensmaster Flex 1800 1820 2100 2120 This page is intentionally blank...

Page 20: ...Greensmaster Flex 1800 1820 2100 2120 Page 3 2 Engine This page is intentionally blank...

Page 30: ...Greensmaster Flex 1800 1820 2100 2120 Page 3 12 Engine This page is intentionally blank...

Page 148: ...Greensmaster Flex 1800 1820 2100 2120 Page 7 30 Cutting Unit This page is intentionally blank...