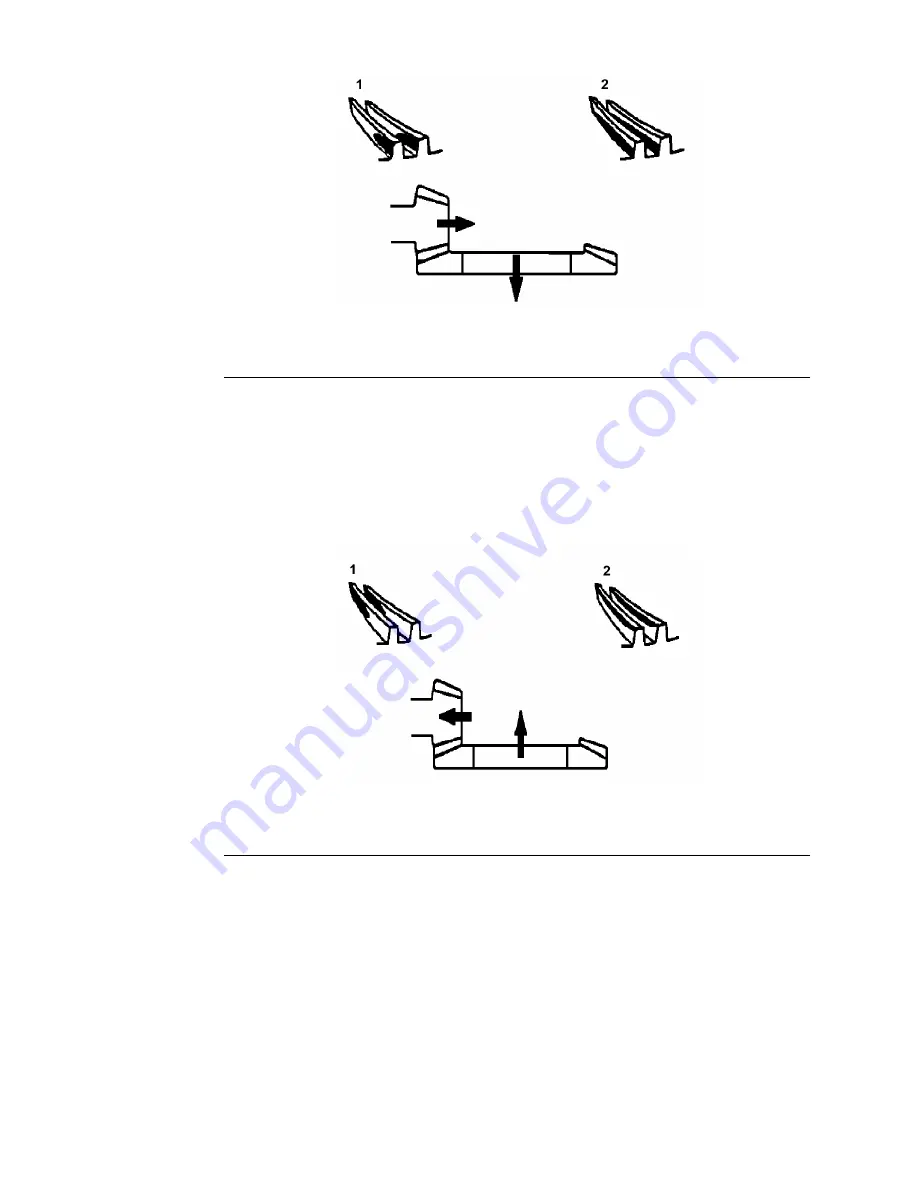

Gear Pattern Movement Summary (continued)

g226503

Figure 285

1.

Heel contact

2.

Base contact

1. If contact is toward the heel or base of the gear (

), do as follows:

A. Install the thicker or additional bearing case shim(s) to move the pinion

shaft toward the ring gear.

B. Install the thinner or remove differential bearing shim(s) to move the ring

gear backward.

C. Repeat until proper tooth contact and pinion gear to ring gear backlash

are correct.

g226504

Figure 286

1.

Toe contact

2.

Tip contact

2. If contact is toward the toe or tip of the gear (

), do as follows:

A. Install the thinner or remove bearing case shim(s) to move the pinion

shaft away from the ring gear.

B. Install the thicker or additional differential bearing shim(s) to move the

ring gear forward.

C. Repeat until proper tooth contact and pinion gear to ring gear backlash

are correct.

Drive Axles: Service and Repairs

Page 8–72

Groundsmaster

®

3280-D/3320

05138SL Rev B

Summary of Contents for Groundsmaster 3280-D

Page 4: ...NOTES Revision History Page 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 10: ...Preface Page 10 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 56: ...Gasoline Engine Service and Repairs Page 3 22 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 84: ...Diesel Engine Service and Repairs Page 4 28 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 228: ...Hydraulic System Service and Repairs Page 5 144 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 430: ...PTO System Service and Repairs Page 9 12 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 466: ...Operator Cab Service and Repairs Page 11 16 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 470: ...Foldout Drawings Page A 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 508: ......