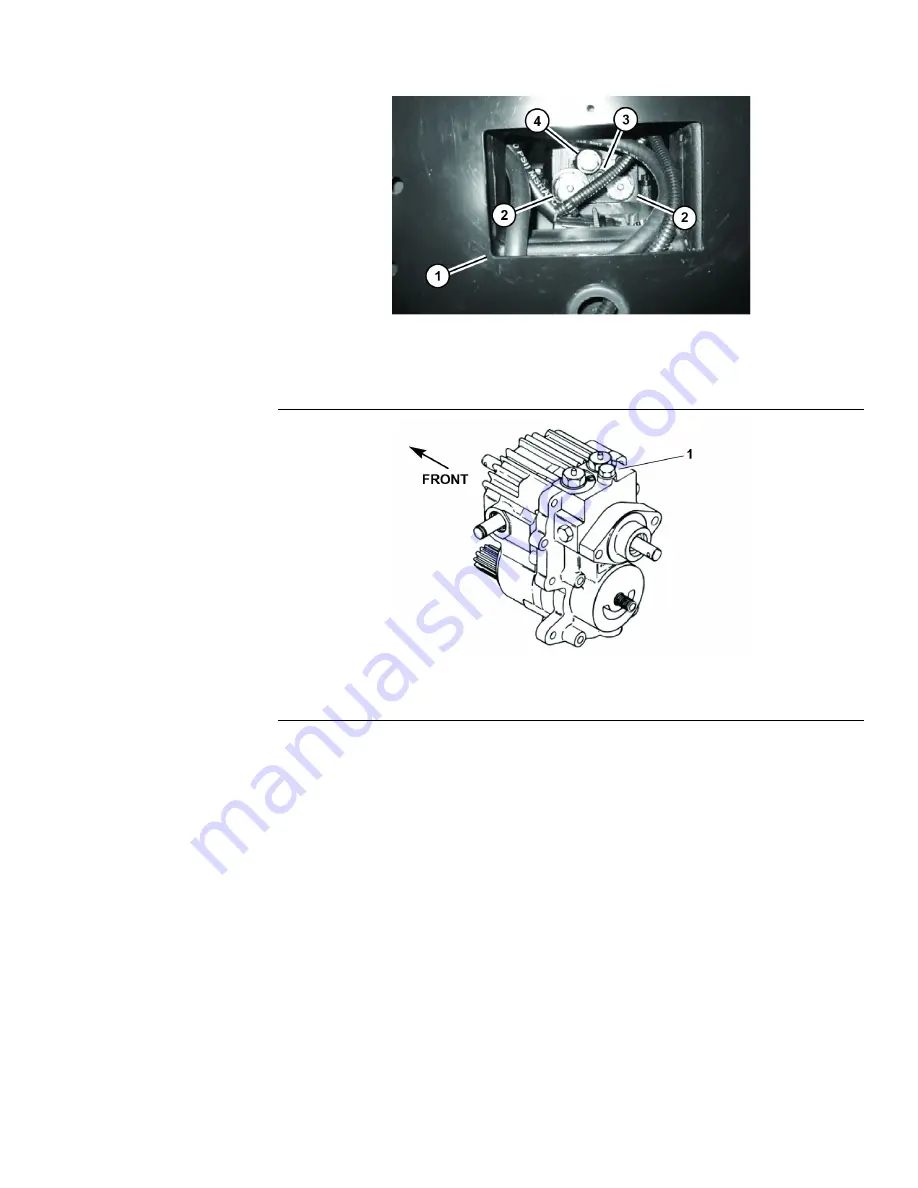

Implement Relief Pressure Test (Using Pressure Gauge) (Machine

Serial Numbers below 316000000)

g230803

Figure 61

1.

Seat base opening

3.

Pipe plug

2.

Check valve

4.

Implement relief valve

g230804

Figure 62

1.

Relief valve

The implement relief pressure test should be done if a problem is suspected

with the implement relief valve.

Note:

When conducting the Implement Relief Pressure Test, use a 34,500 kPa

(5,000 psi) Pressure Gauge.

1. Perform steps 1 through 8 of the

Charge Pressure Test (Using Pressure

Gauge) (Machine Serial Numbers below 316000000) (page 5–49)

. Ensure

to use a 34,500 kPa (5,000 psi) Pressure Gauge.

2. With the engine running at 3,200 rpm, move the lift control lever to the R

AISE

position and allow the cutting unit (or implement) to fully raise. Continue to

hold the lever in the R

AISE

position and observe the pressure gauge. The

pressure reading should be from 4,820 to 6,900 kPa (700 to 1,000 psi) as the

implement relief valve lifts.

3. Move the lift control lever to the L

OWER

position to lower the cutting deck (or

implement) to the ground. Shut off the engine. Record test results.

Groundsmaster

®

3280-D/3320

Page 5–51

Hydraulic System: Testing the Hydraulic System

05138SL Rev B

Summary of Contents for Groundsmaster 3280-D

Page 4: ...NOTES Revision History Page 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 10: ...Preface Page 10 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 56: ...Gasoline Engine Service and Repairs Page 3 22 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 84: ...Diesel Engine Service and Repairs Page 4 28 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 228: ...Hydraulic System Service and Repairs Page 5 144 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 430: ...PTO System Service and Repairs Page 9 12 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 466: ...Operator Cab Service and Repairs Page 11 16 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 470: ...Foldout Drawings Page A 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 508: ......