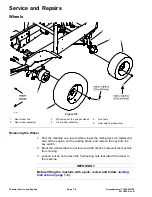

Removing the Wheel (continued)

4. Lift the machine with a jack until the wheel to be removed is off the ground.

Support the machine with appropriate jack stands.

5. Remove the 5 wheel-lug nuts that attach the wheel to the machine, and

remove the wheel.

Installing the Wheel

1. Install the wheel to the machine with the 5 wheel-lug nuts.

2. Lower the machine to the ground.

WARNING

Failure to maintain proper torque could result in failure or loss of

wheel and may result in personal injury.

Maintain the proper torque of the wheel-lug nuts.

3. Torque the front wheel-lug nuts evenly to

102 to 115 N∙m (75 to 85 ft-lb)

in a crossing pattern.

4. Torque the rear wheel-lug nuts evenly to

102 to 122 N∙m (75 to 90 ft-lb)

in a crossing pattern.

5. Check and adjust the tire pressures; refer to

Specifications (page 7–2)

.

Groundsmaster

®

3280-D/3320

Page 7–5

Chassis: Service and Repairs

05138SL Rev B

Summary of Contents for Groundsmaster 3280-D

Page 4: ...NOTES Revision History Page 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 10: ...Preface Page 10 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 56: ...Gasoline Engine Service and Repairs Page 3 22 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 84: ...Diesel Engine Service and Repairs Page 4 28 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 228: ...Hydraulic System Service and Repairs Page 5 144 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 430: ...PTO System Service and Repairs Page 9 12 Groundsmaster 3280 D 3320 05138SL Rev B ...

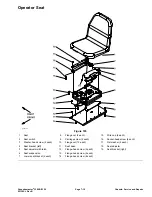

Page 466: ...Operator Cab Service and Repairs Page 11 16 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 470: ...Foldout Drawings Page A 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 508: ......