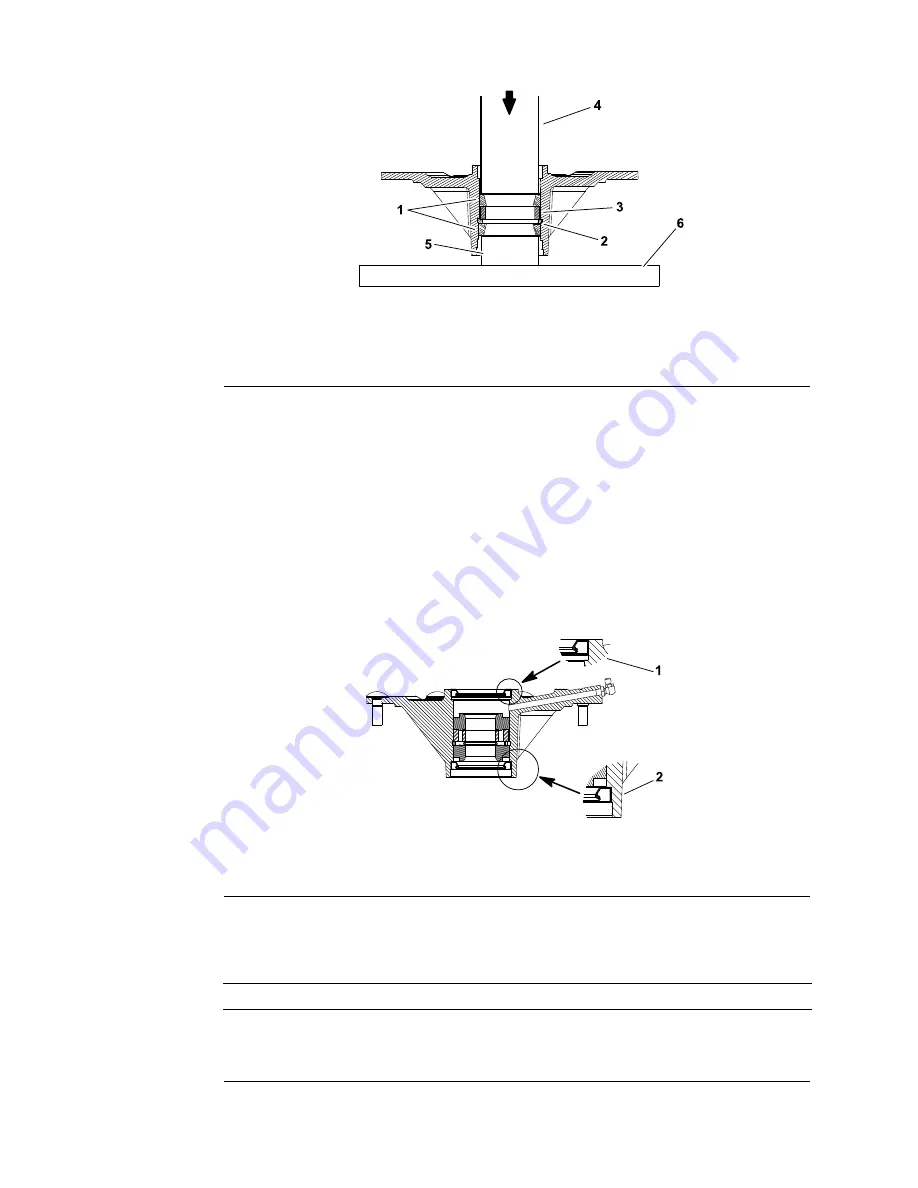

Assembling the Blade Spindle (continued)

g223664

Figure 300

1.

Bearing cup

3.

Outer spacer

5.

Support

2.

Large snap ring

4.

Arbor press

6.

Arbor press base

3. Use an arbor press to push the bearing cups into the top and bottom of the

spindle housing (

).

Note:

The top bearing cup must contact the outer spacer that was previously

installed, and the bottom bearing cup must contact the snap ring.

Note:

Ensure that the assembly is correct by supporting the first bearing cup

and pressing the second bearing cup against it.

4. Pack the bearing cones with grease. Apply a film of grease on the lips of the

oil seals and O-ring.

5. Install the lower bearing cone and oil seal into the bottom of the spindle

housing.

g223665

Figure 301

1.

Upper seal installation

2.

Bottom seal installation

Note:

The bottom seal must have the lip facing out (down). This seal

installation allows grease to purge from the spindle during the lubrication

process (

IMPORTANT

If you are replacing the bearings, ensure that you use the spacer ring

that is included with a new bearing set (

).

Cutting Units: Service and Repairs

Page 10–12

Groundsmaster

®

3280-D/3320

05138SL Rev B

Summary of Contents for Groundsmaster 3280-D

Page 4: ...NOTES Revision History Page 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 10: ...Preface Page 10 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 56: ...Gasoline Engine Service and Repairs Page 3 22 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 84: ...Diesel Engine Service and Repairs Page 4 28 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 228: ...Hydraulic System Service and Repairs Page 5 144 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 430: ...PTO System Service and Repairs Page 9 12 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 466: ...Operator Cab Service and Repairs Page 11 16 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 470: ...Foldout Drawings Page A 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 508: ......