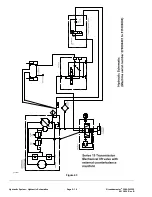

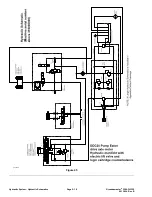

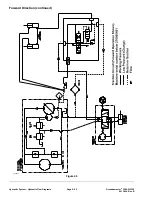

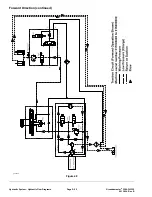

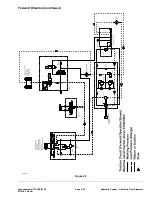

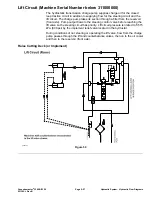

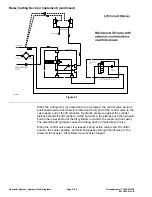

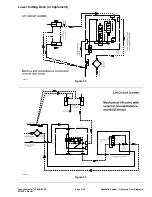

Hydraulic Schematics

g243932

Figure 42

Groundsmaster

®

3280-D/3320

Page 5–15

Hydraulic System: Hydraulic Schematics

05138SL Rev B

Summary of Contents for Groundsmaster 3280-D

Page 4: ...NOTES Revision History Page 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 10: ...Preface Page 10 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 56: ...Gasoline Engine Service and Repairs Page 3 22 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 84: ...Diesel Engine Service and Repairs Page 4 28 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 228: ...Hydraulic System Service and Repairs Page 5 144 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 430: ...PTO System Service and Repairs Page 9 12 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 466: ...Operator Cab Service and Repairs Page 11 16 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 470: ...Foldout Drawings Page A 4 Groundsmaster 3280 D 3320 05138SL Rev B ...

Page 508: ......