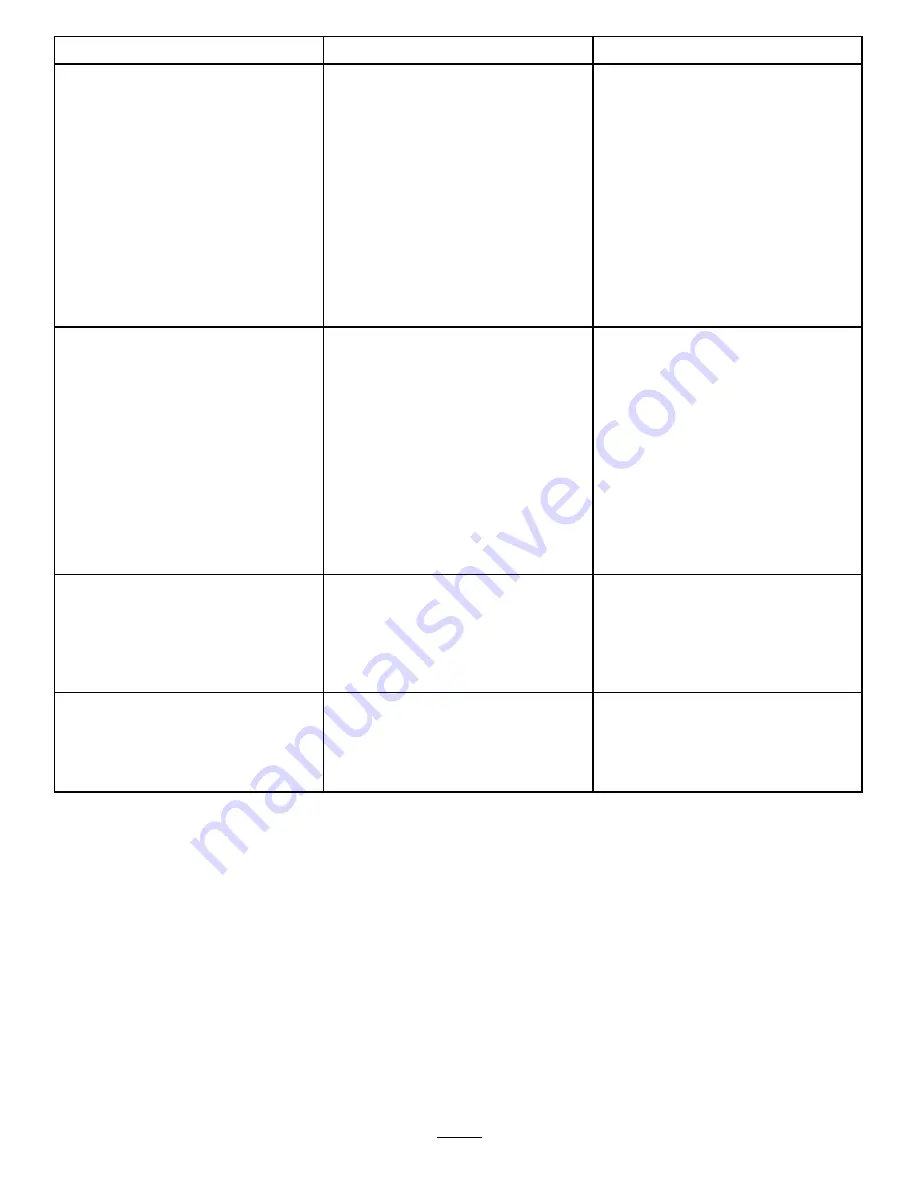

Problem

Possible Cause

Corrective Action

1. There is a faulty pump.

1. Identify the noisy pump and service or

replace.

2. There is a faulty motor.

2. Identify the noisy motor and service or

replace.

3. There is air leaking into the system.

3. Tighten or replace hydraulic fittings,

particularly in suction lines.

4. The suction strainer is blocked or

damaged.

4. Clean and replace the suction strainer.

5. There is excessive oil viscosity due to

cold conditions.

5. Allow the system to warm up.

6. The relief-valve setting is low.

6. Have the relief valve cleaned and

pressure checked. Contact an

Authorized Service Dealer.

There is excessive noise in the hydraulic

system.

7. The hydraulic-fluid level is low.

7. Fill the hydraulic-fliud reservoir to the

correct level.

1. There is a worn pump or motor.

1. Replace as the pump or motor.

2. The hydraulic-oil level is low.

2. Fill the hydraulic-fluid reservoir to the

correct level.

3. The hydraulic-oil viscosity is incorrect.

3. Replace the oil in hydraulic tank with

correct viscosity of oil.

4. The oil-filter element is blocked.

4. Change the filter element.

5. The pressure relief valve does not

function.

5. Have the relief valve cleaned and

pressure checked. Consult your

authorized dealer.

6. There is overheating.

6. Reduce the work rate by increasing the

height of cut or reducing your forward

speed.

After initial operation, the machine loses

power.

7. There are leaks in the suction hose.

7. Check and tighten fittings. Replace

hose if necessary.

1. Lift cylinder seal failure.

1. Replace seals.

2. Pressure-relief valve is jammed open

or wrongly set.

2. Have relief valve cleaned and pressure

checked. Consult your authorized

dealer.

3. The control valve is not functioning.

3. Overhaul the control valve.

Cutting unit fails to lift out of work.

4. There is a mechanical blockage.

4. Remove the blockage.

1. There is tightness in the pivots.

1. Release and grease the pivots as

needed.

2. Mower operated in the Hold position.

2. Move position-control switch to the

Down/Float position.

Cutting unit does not follow ground

contours.

3. The weight transfer set too high.

3. Reduce the weight transfer.

47

Summary of Contents for Groundsmaster 3400

Page 49: ...Notes...

Page 50: ...Notes...