Important:

Use of any other filter may void the

warranty on some components.

1.

Position the machine on a level surface, lower

the cutting units, engage the parking brakes,

shut off the engine, and remove the key from

the ignition.

2.

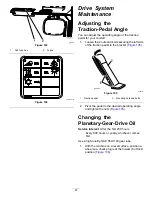

Replace the hydraulic filters (

g031621

Figure 118

3.

Start the engine and let it run for about 2 minutes

to purge air from the system and shut off the

engine and check for leaks.

Checking the Hydraulic Lines and

Hoses

Service Interval:

Every 2 years

Inspect the hydraulic lines and hoses daily for

leaks, kinked lines, loose mounting supports, wear,

loose fittings, weather deterioration, and chemical

deterioration. Make all necessary repairs before

operating the machine.

Adjusting the Counterbalance

Pressure

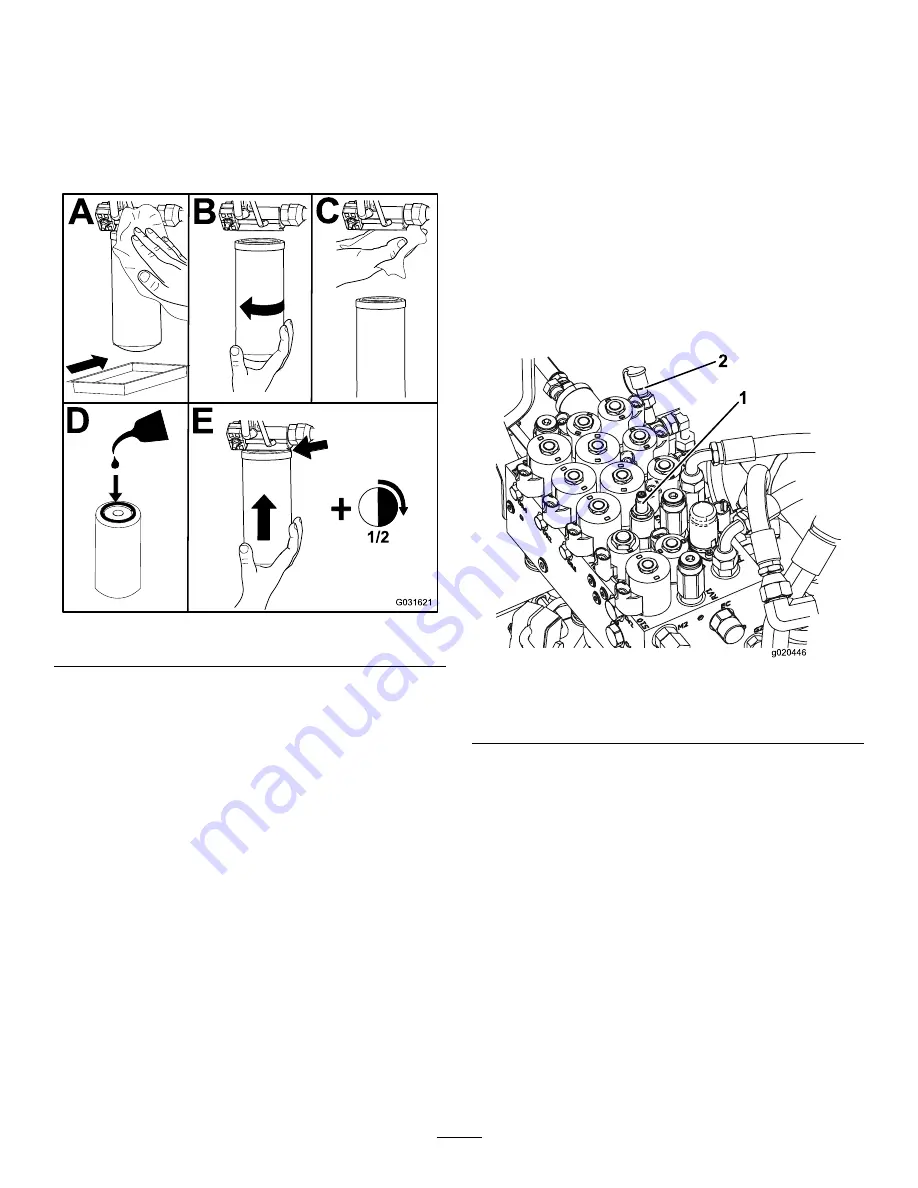

The counterbalance test port is used to test the

pressure in the counterbalance circuit (

The recommended counterbalance pressure is

2241 kPa (325 psi). To adjust the counterbalance

pressure, loosen the locknut, rotate the adjusting

screw (

) clockwise to increase the pressure

or counterclockwise to decrease the pressure, and

tighten the locknut. The engine must be running and

the deck lowered and in the float position to check

the pressure.

Note:

The caster wheels of all 3 cutting units

should remain on the ground when adjusting the

counterbalance and with counterbalance applied.

g020446

Figure 119

1.

Counterbalance-adjusting

screw

2.

Counterbalance-test port

75

Summary of Contents for Groundsmaster 4000

Page 85: ...Notes ...