Tensioning the Blade-Drive

Belts

Service Interval:

After the first 10 hours

Every 50 hours

When properly tensioned, the inside measurement

of the extension spring (hook to hook) should be

approximately 8.3 to 9.5 cm (3-1/4 to 3-3/4 inches).

Once the correct spring tension is attained, adjust the

stop bolt (carriage bolt) until there is approximately 2

to 5 mm (0.065 to 0.185 inch) clearance between the

head of the bolt and the idler arm (

).

Note:

Ensure that the belt is positioned on the spring

side of the belt guide (

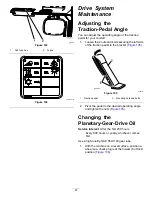

g037383

Figure 114

1.

Extension spring

5.

Measurement (hook to

hook)—approximately 8.3

to 9.5 cm (3-1/4 to 3-3/4

inches)

2.

Stop bolt

6.

Eye bolt

3.

Flange nut

7.

Belt

4.

Belt guide

Replacing the Blade-Drive

Belt

Service Interval:

Every 800 hours

The blade-drive belt, tensioned by the spring-loaded

idler pulley, is very durable. However, after many

hours of use, the belt will show signs of wear. Signs of

a worn belt include squealing when the belt is rotating,

blades slipping when cutting grass, frayed edges,

burn marks, and cracks. Replace the belt if any of

these conditions are evident.

1.

Lower the cutting unit to the shop floor, remove

the belt covers from the top of the cutting unit,

and set the covers aside.

2.

Loosen the eye bolt allowing the removal of the

extension spring (

3.

Loosen the flange nut securing the stop bolt to

the mounting tab and move the idler pulley away

from the belt to release the belt tension (

Note:

Loosen the nut enough to allow the idler

arm to pass the stop bolt.

Note:

If the stop bolt is ever removed from the

mounting tab, make sure that it is installed again

in the hole that aligns the stop-bolt head with

the idler arm.

4.

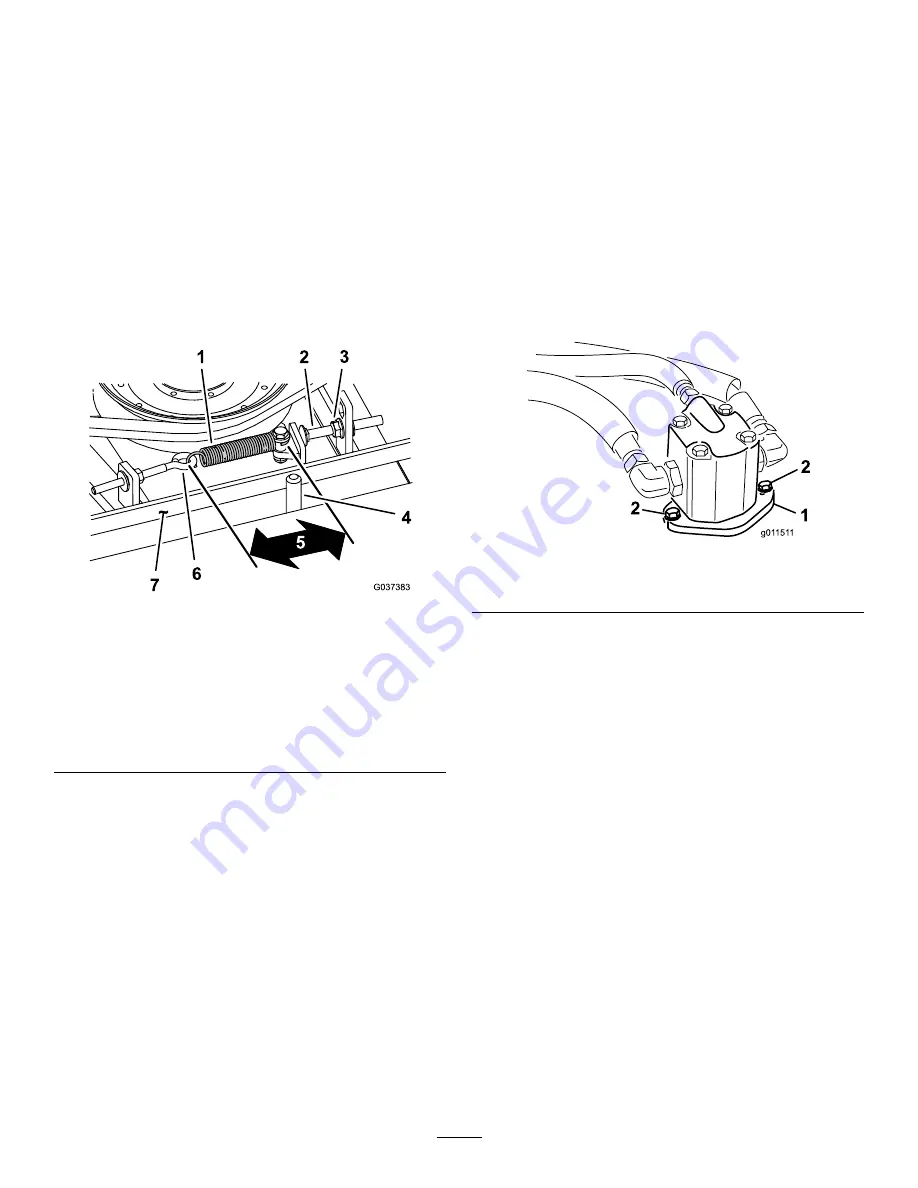

Remove the bolts securing the hydraulic motor

to the cutting unit (

g011511

Figure 115

1.

Hydraulic motor

2.

Mounting bolts

5.

Lift the motor off the cutting unit and lay it on top

of the cutting unit.

6.

Remove the old belt from around the spindle

pulleys and idler pulley.

7.

Route the new belt around the spindle pulleys

and idler-pulley assembly.

8.

Position the hydraulic motor on the cutting

unit after routing the belt around the pulleys.

Mount the motor to the cutting unit with the bolts

previously removed.

Note:

Ensure that the belt is positioned on the

spring side of the belt guide (

9.

Connect the extension spring (

) to the

eye bolt and tension the belt as follows:

•

When properly tensioned, the inside

measurement of the extension spring (hook

to hook) should be approximately 8.3 to 9.5

cm (3-1/4 to 3-3/4 inches).

•

When you attain the correct spring tension,

adjust the stop bolt (carriage bolt) until there

is approximately 2 to 5 mm (0.065 to 0.185

inches) clearance between the head of the

bolt and the idler arm.

72

Summary of Contents for Groundsmaster 4000

Page 85: ...Notes ...