Blade Maintenance

Blade Safety

•

Inspect the blade periodically for wear or damage.

•

Use care when checking the blades. Wrap the

blades or wear gloves, and use caution when

servicing the blades. Only replace or sharpen the

blades; never straighten or weld them.

•

On multi-bladed machines, take care as rotating 1

blade can cause other blades to rotate.

Checking for a Bent Blade

After striking a foreign object, inspect the machine

for damage and make repairs before starting

and operating the equipment. Torque all of the

spindle-pulley nuts to 176 to 203 N∙m (130 to 150

ft-lb).

1.

Position the machine on a level surface, raise

the cutting unit, engage the parking brake, put

the traction pedal in

NEUTRAL

, put the PTO lever

in the O

FF

position, shut off the engine, and

remove the ignition key.

Note:

Block the cutting unit to prevent it from

accidentally falling.

2.

Rotate the blade until the ends face forward and

backward and measure from the inside of the

cutting unit to the cutting edge at the front of the

blade (

Note:

Remember this dimension.

g004740

Figure 126

3.

Rotate the opposite end of the blade forward

and measure between the cutting unit and

cutting edge of the blade at the same position

as in step

Note:

The difference between the dimensions

obtained in steps

and

must not exceed 3 mm

(1/8 inch). If the dimension exceeds 3 mm (1/8

inch), the blade is bent and must be replaced;

refer to

Removing and Installing the Cutting-Unit

.

Removing and Installing

the Cutting-Unit Blade(s)

Replace the blade if it hits a solid object, is out

of balance, or is bent. Always use genuine Toro

replacement blades to ensure safety and optimum

performance.

1.

Park the machine on a level surface, raise the

cutting unit to the highest position, engage the

parking brake, shut off the engine, and remove

the key.

Note:

Block the cutting unit to prevent it from

accidentally falling.

2.

Grasp the end of the blade using a rag or

thickly-padded glove.

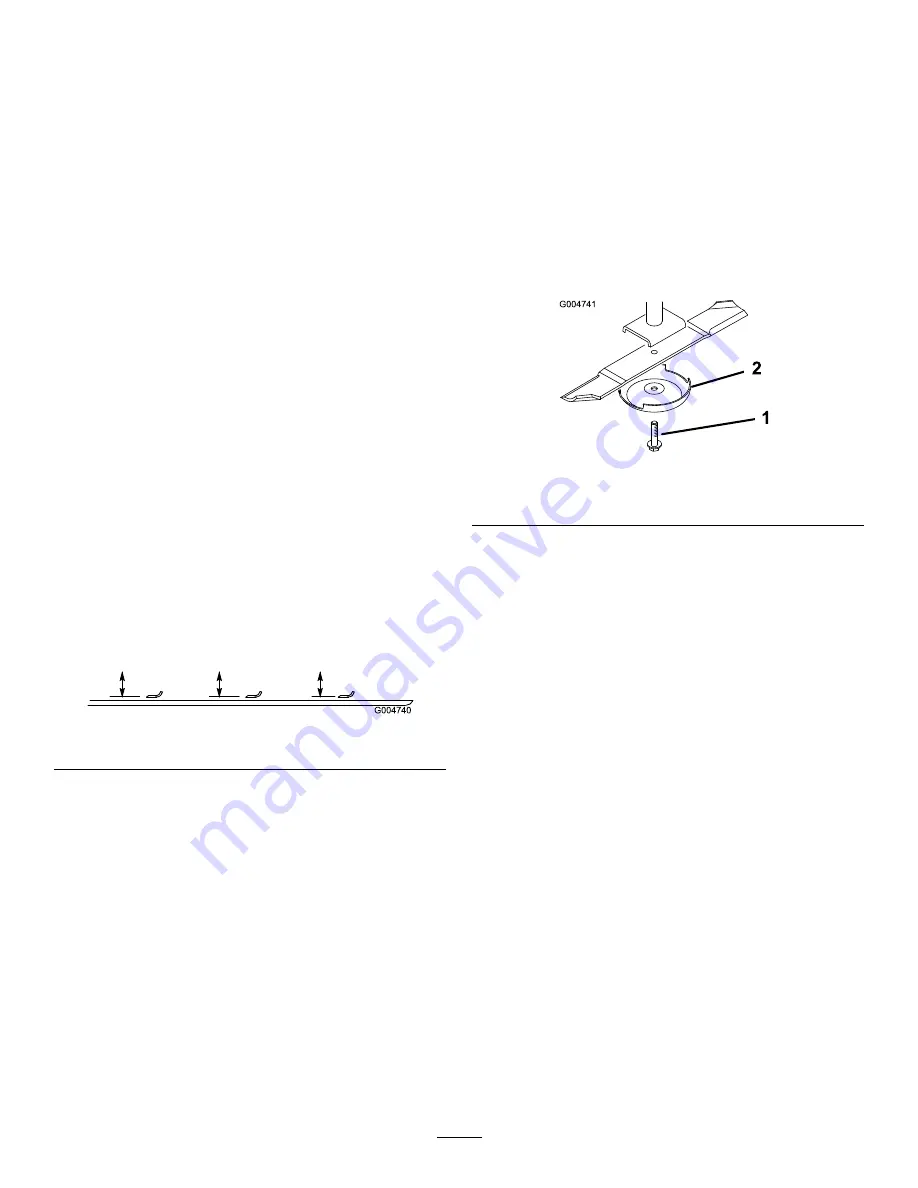

3.

Remove the blade bolt, anti-scalp cup, and

blade from the spindle shaft (

g004741

Figure 127

1.

Blade bolt

2.

Anti-scalp cup

4.

Install the blade, anti-scalp cup, and blade bolt

and tighten the blade bolt to 115 to 149 N∙m (85

to 110 ft-lb).

Important:

The curved part of the blade

must be pointing toward the inside of the

cutting unit to ensure proper cutting.

Note:

After striking a foreign object, torque all

spindle-pulley nuts to 115 to 149 N∙m (85 to 110

ft-lb).

Inspecting and Sharpening

the Cutting Unit Blade(s)

Both cutting edges and the sail, which is the turned-up

portion opposite of the cutting edge, contribute to a

good quality of cut.

Maintain sharp blades throughout the cutting season.

Sharp blades create a clean cut without tearing or

shredding the grass blades.

Check the blades for any wear or damage. The sail

lifts the grass up straight, thereby producing an even

cut and gradually wears down during operation.

1.

Park the machine on a level surface, raise the

cutting unit, engage the parking brake, put the

traction pedal in

NEUTRAL

, put the PTO lever

in the O

FF

position, shut off the engine, and

remove the key from the ignition.

79

Summary of Contents for Groundsmaster 4000

Page 85: ...Notes ...