39

GTS 200

Electric Starter

D. Battery faulty or damaged.

E. Incorrect rotation due to reversed motor polarity or

reverse battery connections – motor rotates

counterclockwise viewed from pinion gear.

4. Starter Motor Spins, Will Not Stop

A. Defective starter switch.

Test Equipment

The following is a list of equipment recommended to test and

repair starter motors , and to test batteries.

Digital Multimeter

A Digital Multimeter is recommended. The meter may be

used to read volts, ohms or amperes, and test diodes

(rectifiers) when test leads are inserted in the appropriate

receptacle, Fig. 85.

Fig. 85 – Digital Multimeter

DC Shunt

Use with Digital Multimeter. The DC Shunt may be used to

read starter motor current draw on 12 volt starter motors. Use

Briggs & Stratton Tool #19359, Fig. 86.

Fig. 86 – DC Shunt

Tachometer

A Trysit Sirometer (Tachometer) is available from your Briggs

& Stratton source of supply. Use Briggs & Stratton Tool

#19200. The Sirometer measures from 800 to 25,000

revolutions per minute (RPM), Fig. 87.

Fig. 87 – Trysit Sirometer (Tachometer)

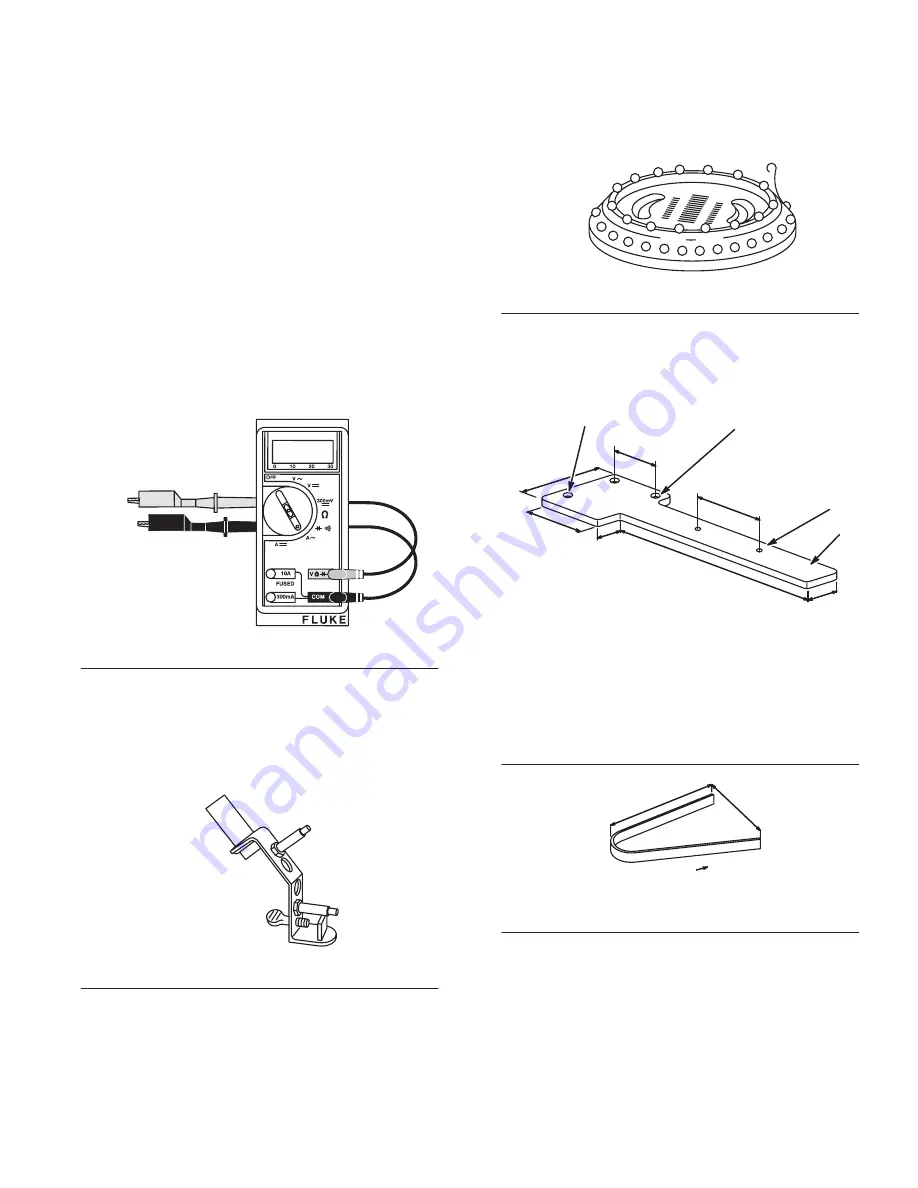

Starter Test Bracket

A starter motor test bracket may be made as shown in Fig. 88.

2–1/4”

(57mm)

3–1/2” (89mm)

2” (51mm)

10” (254mm)

1” (25mm)

3–1/2”

(89mm)

4”

(102mm)

1

2

3

4

Fig. 88 – Starter Mounting Test Bracket

1.

Extra hole for mounting

starter brackets

2.

Drill two holes 3/8”

(10mm) diameter for

starter mounting bracket

3.

Drill two holes for

mounting Briggs &

Stratton Tool #19200

tachometer #7 drill tap

hole for 1/4–20 NC screws

4.

Metal stock 1/4” (6mm)

thick steel

2” (51mm)

5/8”

(16mm)

2–1/4” (57mm)

Fig. 89 – Brush Spreader

Other Equipment

A growler or armature tester (checks armature for continuity,

shorts and opens) is available from an Automobile Diagnostic

Service supplier.

A known good 12 volt battery is required when testing 12 volt

starting systems.