6

GTS 200

General Information

Change Oil—Drain Plug Method

1. Run engine at least 5 minutes to warm the oil. Warm oil

drains more easily and more of the contaminants are

removed.

2. Remove oil drain plug (Fig. 2). Drain oil into a pan.

1

Fig. 2 – Drain Plug Location

1.

Oil drain plug

3. If replacing the oil filter (on models so equipped), do so at

this time.

4. Install drain plug snugly.

5. Remove dipstick and refill slowly with new oil of proper

service classification and viscosity grade.

6. Start and run engine at idle. Check for oil leaks.

7. Stop engine. Recheck oil level and add oil if required.

Change Oil—Oil Fill Tube Method

1. Stop engine and wait for all moving parts to stop. Pull wire

off spark plug.

2. Remove grass bag. Drain gasoline from fuel tank.

3. Remove dipstick from oil fill tube and place a drain pan

next to left side of mower.

4. Tip mower on its left side, allowing oil to drain into drain

pan (Fig. 3).

m–3848

1

2

Fig. 3

1.

Oil fill tube

2.

Oil filter

5. If replacing the oil filter (on models so equipped), do so at

this time.

6. When oil is drained, return mower to upright position and

add fresh oil to engine. Refer to Oil in this section.

Approximate Crankcase Oil Capacity (Dry)

Specifications

Without oil filter

22 oz.

. . . . .

.65 Liter

With oil filter

26 oz.

. . . . . . . .

.78 Liter

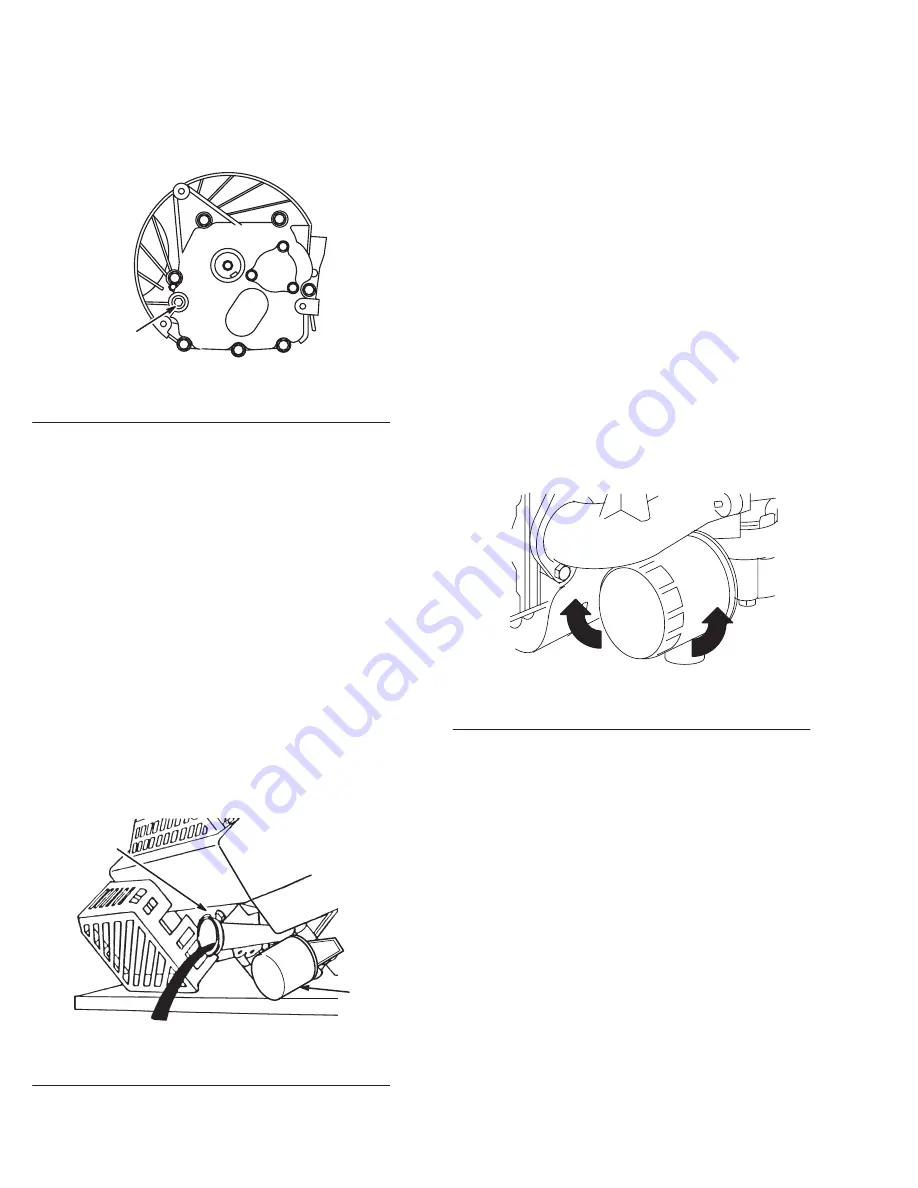

Change Oil Filter

(on models so equipped)

Change filter every 100 hours. Before installing new filter,

lightly oil filter gasket with fresh clean engine oil. Screw filter

clockwise by hand until gasket contacts filter adapter. Tighten

1/2 to 3/4 turn farther. Add fresh oil. Then, start and run

engine at idle for 30 seconds and stop engine. Recheck oil

level and add oil if required. Restart engine and check for oil

leaks, Fig. 4.

1

2

Fig. 4 – Remove and Install Oil Filter

1.

Install

2.

Remove