29

GTS 200

Compression

Remove Valves

1. Place cylinder head on work surface.

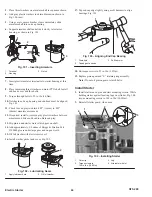

2. Remove valve cap from valve stems, Fig. 52.

1

2

Fig. 52 – Removing Valves

1.

Valve spring retainer

2.

Valve cap

3. With thumbs, press down on valve spring retainer and

spring to compress until large end of slot in retainer can

line up with end of valve stem, Fig. 52.

4. Release pressure on retainer and spring.

5. Remove retainer, spring, and intake valve seal, if removing

intake valve, Fig. 52.

Inspect Valve Guides

1. Measure intake and exhaust valve guides using Briggs &

Stratton Tool #19122.

2. If flat end of gauge can enter guide for 1/4” (6.35mm) or

more, cylinder head must be replaced.

3. If plug gauge is not available, refer to Table No. 1,

Page 32 for reject size.

Valve Service

Reface Valves and Seats

Although valve faces can be resurfaced on a commercially

available valve grinding tool, we do not recommend this

practice as a high quality repair procedure. Valve replacement

is recommended for damaged or worn valves. Valve seats are

cut using Briggs & Stratton Tool #19237 or #19343, Neway

Valve Seat Cutter Kit, to 45

°

on exhaust and some intake

seats. Other intake seats are cut to 30

°

. Valve and seat are

lapped in using Briggs & Stratton Tool #19258, Valve Lapping

Tool, and Briggs & Stratton Part #94150, Valve Lapping

Compound, to assure a good seal between the valve face and

the seat.

1. Thoroughly clean lapping compound from valve seat and

valve face.

2. Valve seat width should be as shown in Fig. 53.

1

3

2

45

°

4

Fig. 53 – Valve and Seat Dimensions

1.

Margin

2.

1/32” (.79mm) fit for use

3.

1/64” (.38mm) discard

4.

Valve seat width minimum

3/64–1/16” (1.17–1.57mm)

3. If seat is wider, a narrowing cutter should be used. If valve

face is badly burned, the burned valve should be replaced.

4. Replace valve if margin is 1/64 inch (.39mm) or less or

damaged, Fig. 53.

If seats are burned or damaged, replace cylinder head.

Assemble Cylinder Head

Install Cylinder Head Plate and

Rocker Arm Studs

1. Place new cylinder plate gasket and cylinder head plate on

cylinder head.

2. Install and torque two (2) cylinder plate screws to

80 in. lbs. (9.0Nm), Fig. 54.

1

Fig. 54 – Installing Cylinder Head Plate

1.

Screw: torque to 80 in. lbs. (9.0Nm)