Maintenance

Note:

Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first hour

• Check the control cable and adjust it if necessary.

• Check for loose fasteners and tighten them if necessary.

After the first 2 hours

• Change the engine oil.

Before each use or daily

• Check the engine oil level and add oil if necessary.

Yearly

• Check the control cable and adjust it if necessary.

• Inspect the rotor blades and have an Authorized Service Dealer replace the rotor

blades and scraper if necessary.

• Change the engine oil.

• Service the spark plug and replace it if necessary.

• Check for loose fasteners and tighten them if necessary.

• Have an Authorized Service Dealer inspect the drive belt and replace it if necessary.

Yearly or before storage

• Prepare the snowthrower for storage.

Adjusting the Control Cable

Checking the Control Cable

Service Interval:

After the first hour—Check

the control cable and adjust it if

necessary.

Yearly—Check the control cable and

adjust it if necessary.

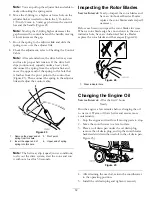

Move the control bar back toward the handle to remove

the slack in the control cable (Figure 21).

Figure 21

1.

Control bar

2.

1/16-inch to 1/8-inch (2

mm to 3 mm) gap

Note:

Ensure that a 1/16-inch to 1/8-inch (2 mm to 3

mm) gap exists between the control bar and the handle

(Figure 21).

Important:

The control cable must contain some

slack when you disengage the control bar for the

rotor blades to stop properly.

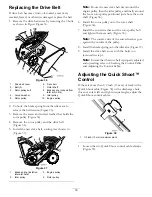

Adjusting the Control Cable

1. Slide up the spring cover and unhook the spring

from the adjuster link (Figure 22).

Figure 22

1.

Adjuster link

3.

Spring cover

2.

Z-fitting

4.

Unhook the spring here.

11