Adjustments

Cutting Unit Belt Adjustment

Cutting unit drive belts should have a maximum deflec

tion of 1/2 in. with 10 lb. load applied to middle of belt

span.

NOTE: When new belts have been installed, check

tension again after the first 8 hours of operation.

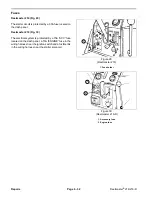

Old Style Belt Tensioner Assembly (Fig. 3)

Loosen jam nut on front end of belt tension rod. Rotate

rod to lengthen or shorten rod to desired length. Tighten

jam nut.

To release belt tension to cutting units:

Figure 3

A. Remove hair pin cotter and pivot belt tension rod

(Old Style Belt Tensioner)

handle outward (away from cutting unit).

1. Belt tension rod handle

3. Jam nut

B. Turn handle 1/2 turn (180

°

) so the angle cut

2. Belt tension rod

4. Angle cut

(beveled edges) of tension rods are parallel. Belt

tension is now released.

C. To tighten the belt, turn belt tension rod handle

1/2 turn (180

°

) back to its previous position and

install hair pin cotter. Angle cuts (beveled edges)

must be oriented toward cutting unit and ends must

make contact when belt is tensioned.

NOTE: For smooth operation, occasionally clean sliding

pin at center of tension rod and coat with anti-seize

compound.

NOTE: Old style belt tension rods can be replaced with

the new style assemblies.

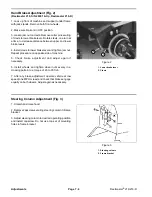

New Style Belt Tensioner Assembly (Fig. 4)

Loosen jam nut on front end of belt tension rod. Rotate

rod to lengthen or shorten rod to desired length. Tighten

jam nut.

To release belt tension to cutting units push retaining

cup rearward and pivot yoke downward.

Figure 4

(New Style Belt Tensioner)

1. Belt tension rod cup retainer

2. Belt tension rod

3. Jam nut

Adjustments

Page 8 - 2

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...