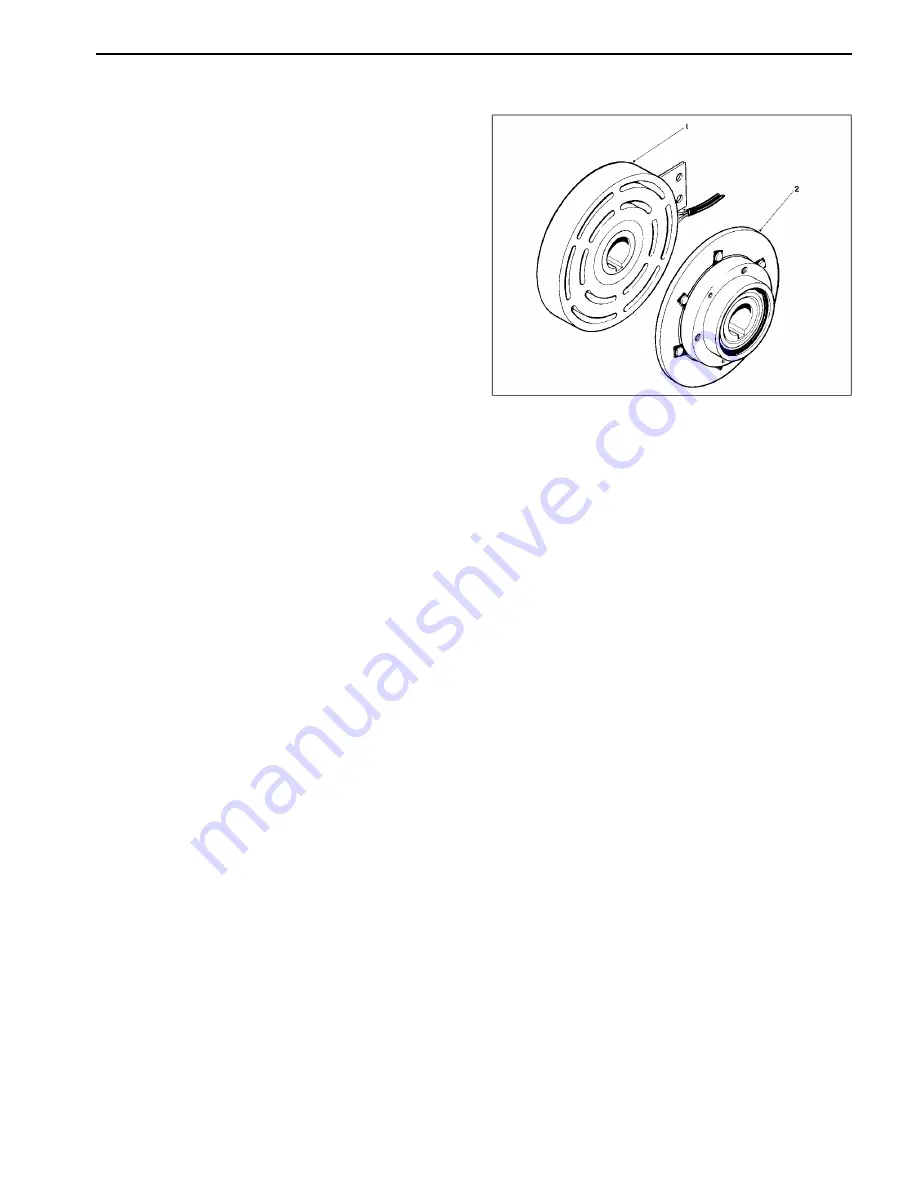

Clutch Service

(Reelmaster 216-D)

(Fig. 12)

The clutch has a rotor and pulley that is driven from the

engine crankshaft by a belt . When the reel engagement

circuit is energized, an electromagnet pulls the armature

into contact with the rotor to drive the jackshaft.

Failure to get clutch engagement would likely be caused

by a clutch air gap that is too large, a circuit fault in the

clutch electromagnet, or other electrical problem (see

Troubleshooting section of Chapter 6 - Electrical Sys

tem).

NOTE: The air gap is not adjustable on this clutch.

The clutch must be serviced in sub-assemblies. Individ

ual parts of the clutch can be replaced. See Jackshaft,

Bearing and Clutch Service (Reelmaster 216-D) for

more information.

Figure 12

1. Field & rotor assembly

2. Armature assembly

Reelmaster

®

216/216-D

Page 8 - 9

Repairs

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...