__________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

Troubleshooting

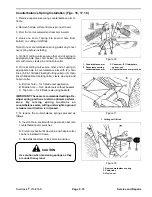

There are a number of factors that can contribute to

height may not always be overcome by adjusting the

unsatisfactory quality of cut, some of which may be turf

machine. It is important to remember that the lower the

conditions. Turf conditions such as excessive thatch,

height of cut, the more critical these factors are.

“sponginess” or attempting to cut off too much grass

Factors Affecting Quality of Cut

Factor

Possible Problem/Correction

1. Engine maximum governed speed.

Check maximum governed engine speed. Adjust to

specification if necessary — affects reel speed.

2. Reel speed and ground speed.

Select proper reel pulley size and use proper ground

speed to get optimum clip frequency for selected

height of cut.

See Troubleshooting in Chapter 5 - Hydraulic System.

3. Tire pressure.

Check tire pressure and adjust if necessary. Must be

equal in both front tires.

4. Reel bearing condition and alignment.

Replace bearings if worn or damaged.

5. Reel and bedknife sharpness.

Reel and/or bedknife that has rounded edge

CANNOT

be corrected by tightening bedknife to reel

contact. Grind reel to remove taper (cone shape)

and/or rifling (grooved or ribbed appearance). Grind

bedknife to sharpen and/or remove rifling. (Most com

mon cause of rifling is bedknife to reel contact that is

too tight.)

NOTE: New bedknife must be ground after installing

on bedbar to match bedknife to bedbar.

6. Bedknife parallel to reel.

Check and adjust as necessary.

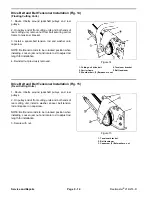

7. Bedknife to reel contact.

Check before operating with cutting unit on ground.

Remove belt tension and rotate reel by hand. TURN

ADJUSTING KNOB ONE (1) CLICK AT A TIME UNTIL

FIRST CONTACT BETWEEN REEL AND BEDKNIFE IS

FELT OR HEARD, THEN TIGHTEN ONE (1) MORE

CLICK TO GET LIGHT CONTACT

. No contact dulls

cutting edges. Excessive contact increases wear.

Troubleshooting

Page 9 - 4

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...