Cutting Unit Characteristics

The single knob bedknife-to-reel adjustment system

incorporated in this cutting unit simplifies the adjustment

procedure needed to deliver optimum mowing perform

ance. The precise adjustment possible with the single

knob/bedbar design gives the necessary control to pro

vide a continual self-sharpening action — thus maintain

ing sharp cutting edges, assuring good quality-of-cut,

and greatly reducing the need for routine backlapping.

In addition, the rear roller positioning system permits

optimum bedknife attitude and location for varying

height-of-cuts and turf conditions.

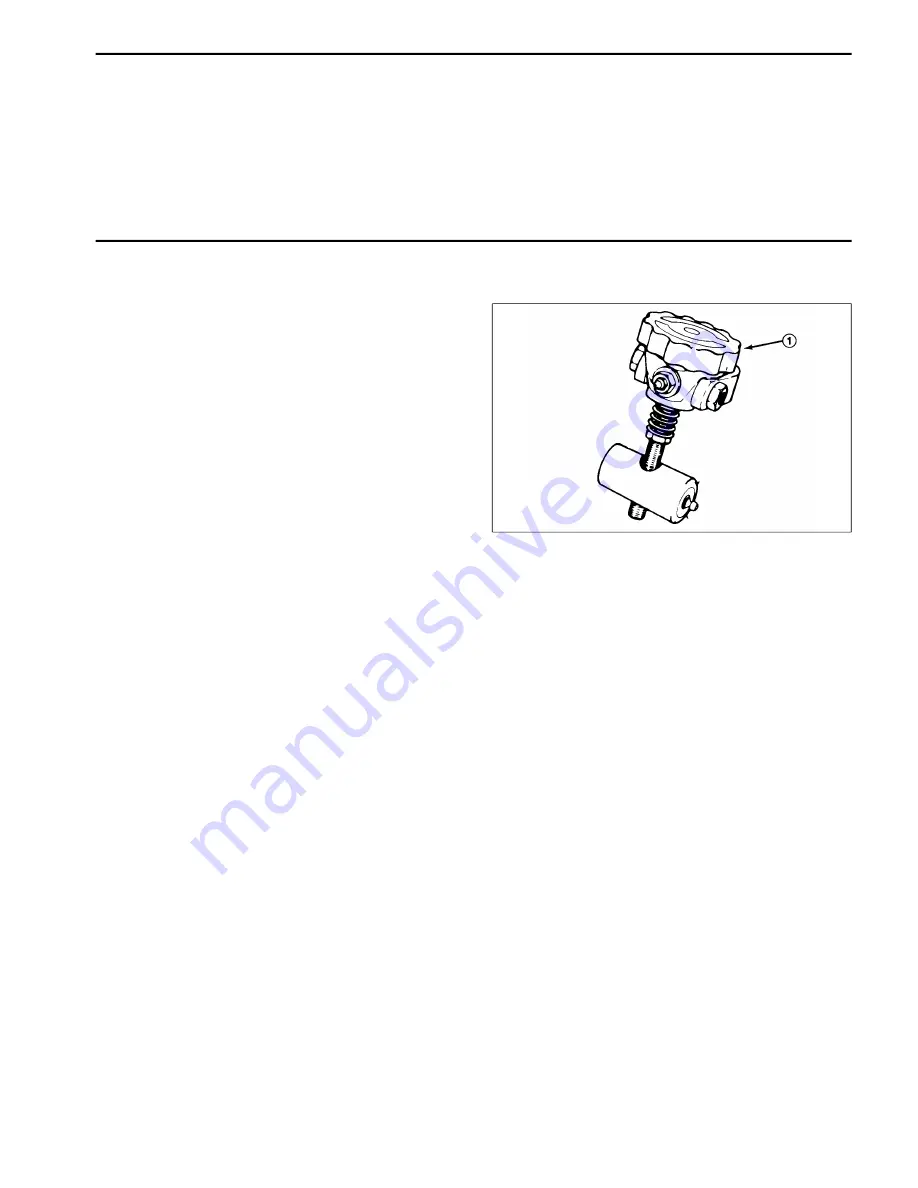

Bedknife to Reel Contact (Fig. 3)

Prior to each day’s mowing, or as required, each cutting

unit must be checked to verify proper bedknife-to-reel

contact. This must be performed even though quality of

cut is acceptable.

1. Shut off engine and lower cutting units onto a hard

surface.

2. Release belt tension to cutting units.

3. Slowly rotate reel in reverse direction listening for

reel-to-bedknife contact. If no contact is evident, turn

bedknife adjusting knob clockwise, one click at a time,

until light contact is felt and heard.

4. If excessive contact is felt, turn bedknife adjusting

knob counterclockwise, one click at a time until no

contact is evident. Then turn bedknife adjusting knob

one click at a time clockwise, until light contact is felt

and heard.

IMPORTANT: Light contact is preferred at all times.

If light contact is not maintained, bedknife / reel

edges will not sufficiently self-sharpen and dull

cutting edges will result after a period of operation.

If excessive contact is maintained, bedknife / reel

wear will be accelerated, uneven wear can result,

and quality of cut may be adversely affected.

NOTE: As the reel blades continue to run against the

bedknife a slight burr will appear on the front cutting

edge surface the full length of the bedknife. If a file is

occasionally run across the front edge to remove this

burr, improved cutting can be obtained.

After extended running, a ridge will eventually develop

at both ends of the bedknife. These ridges must be

ground off or filed flush with cutting edge of bedknife to

assure smooth operation.

Figure 3

1. Bedknife adjusting knob

Reelmaster

®

216/216-D

Page 9 - 7

Set Up and Adjustments

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...