REELMASTER

®

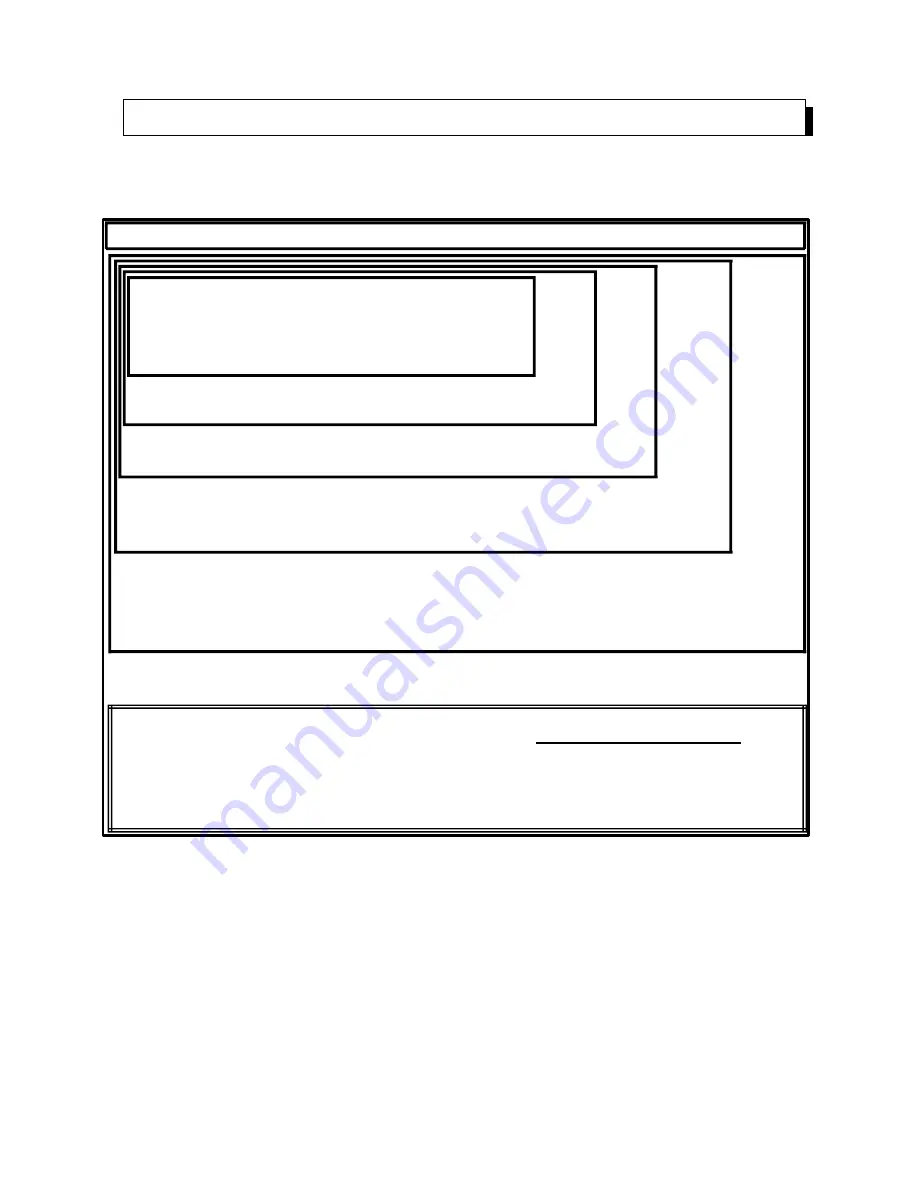

216 Maintenance Schedule

Minimum Recommended Maintenance Intervals:

Maintenance Procedure

Maintenance Interval & Service

Check Battery Fluid/Connections

Lubricate Grease Fittings

Every

25hrs

Every

50hrs

Every

100hrs

Every

200hrs

Every

400hrs

Service Air Filter Pre-Cleaner

A Level

† Change Engine Oil

Service

† Check Traction Belt Tension

B Level

Service Air Filter Paper Element

Service

Service Spark Plug

C Level

† Torque Wheel Lug Nuts

Service

† Replace Hydraulic Filter

Adjust Electric Clutch

D Level

Inspect Traction Linkage Movement

Service

Change Hydraulic Fluid

Decarbon Combustion Chamber

Adjust Valves and Torque Head Bolts

E Level

‡ Check Engine RPM (idle and full throttle)

Service

† Initial break in at 5 hours

‡ Initial break in at 50 hours

Replace Moving Hoses

Replace Safety Switches

Fuel Tank - Drain/Flush

Annual Recommendations:

Items listed are recommended every 1000

hours or 2 years whichever occurs first.

Replace Fuel Filter

Hydraulic Tank - Drain/Flush

(See Operator's and Service Manual for specifications and procedures)

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

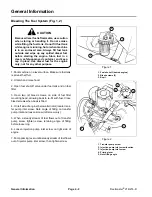

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...