Backlapping

The cutting units may be backlapped in position on the

machine by releasing tensioning to the drive belts and

removing the capscrew securing the left end of the

carrier frame to the cutting unit. Otherwise, remove

cutting units completely before backlapping.

Connect a lapping machine to the capscrew on the left

end of reel shaft with an extension coupler and a 9/16 in.

socket. Backlap according to procedures in the Toro

Sharpening Reel and Rotary Mowers Manual Form No.

80-300-SL.

j

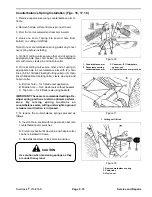

DANGER

Be careful when lapping the reel because

contact with the reel or other moving parts

can result in personal in ury.

Under no circumstances use a short handled

paint brush. 29-9100 Handle assembly com

plete or individual parts are available from

your local Authorized TORO Distributor.

CAUTION

Service and Repairs

Page 9 - 18

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...