_______________________________

_______________________________

______________________________

_______________________________

_______________________________

______________________________

_______________________________

_______________________________

_____________________________

_______________________________

_______________________________

______________________________

_______________________________

_______________________________

______________________________

_______________________________

_______________________________

______________________________

______________________________

_______________________________

_______________________________

______________________________

_______________________________

_______________________________

______________________________

_______________________________

_______________________________

______________________________

_______________________________

_______________________________

REELMASTER

®

Date:______________

216 Supervisor Maintenance Work Order

(duplicate this page for routine use)

Unit Designation:

TORO I.D. #:

Remarks:

____________-____________

Service to perform (circle):

A B C D E Other

Technician:

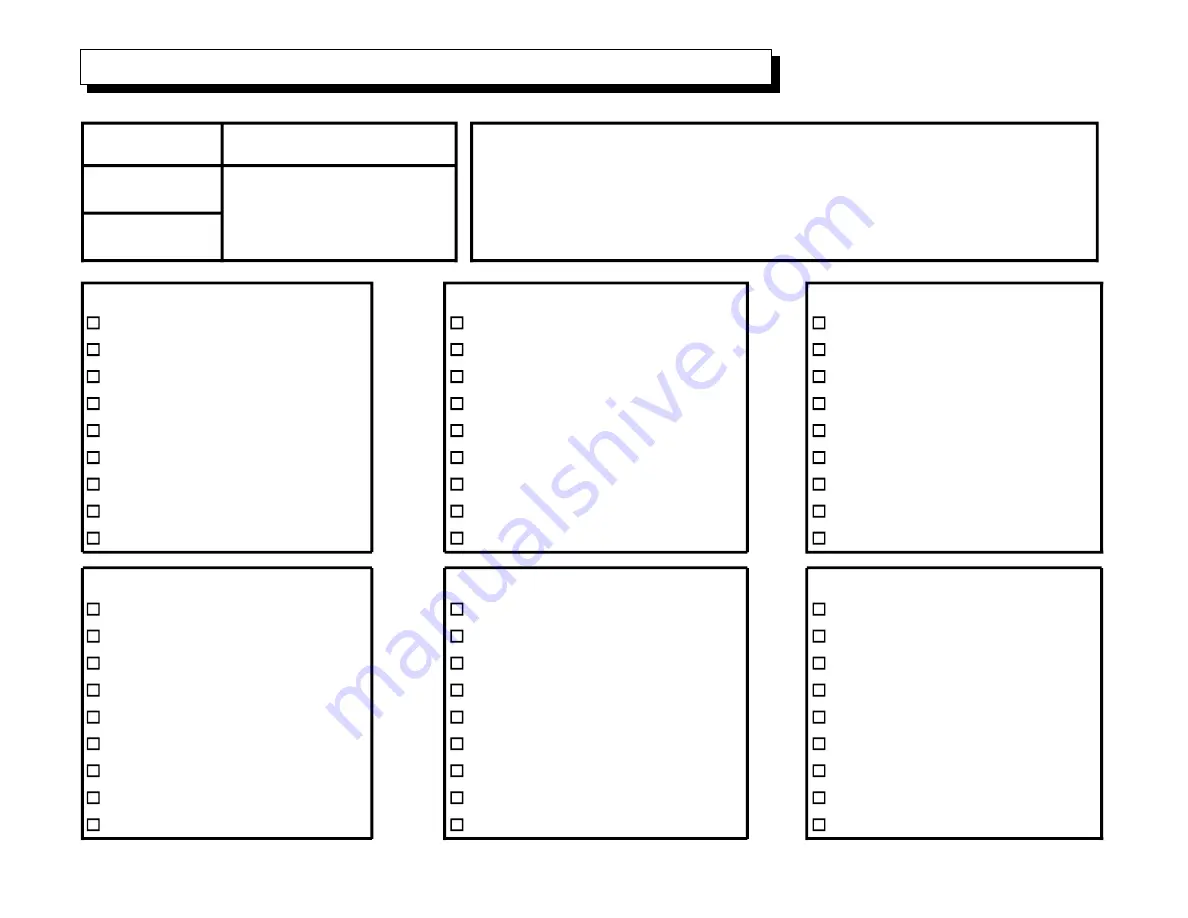

A

B

C

Check Battery Fluid/Connections

Check Traction Belt Tension

Service Spark Plug

Lubricate Grease Fittings

Service Air Filter Paper Element

Torque Wheel Lug Nuts

Service Air Filter Pre-Cleaner

A-Service

required

A

and

B Service

required

Change Engine Oil

_

D

E - Service (every 400 hours)

Other

Replace Hydraulic Filter

Change Hydraulic Fluid

Replace Moving Hoses

Adjust Electric Clutch

Decarbon Combustion Chamber

Replace Safety Switches

Inspect Traction Linkage Movement

Adjust Valves and Torque Head Bolts

Fuel Tank - Drain/Flush

A

,

B

, and

C Service

required

Check Engine RPM (idle & full throttle)

Replace Fuel Filter

A, B, C

, and

required

Hydraulic Tank - Drain/Flush

Hours:

-Service (every 25 hours)

-Service (every 50 hours)

-Service (every 100 hours)

-Service (every 200 hours)

- Annual Service and Specials

D Service

(See Operator's and Service Manual for specifications and procedures)

Form No. 95-845-SL

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

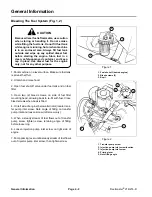

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...